Polyester sewing thread is an essential component in various industries, including textile, garment manufacturing, and industrial product assembly. Its high strength, durability, and versatility make it indispensable for creating long-lasting seams in a wide range of applications.

Among the diverse polyester sewing threads available, Polyester sewing thread 30/2 and Polyester sewing thread 30/3 hold significant positions in the market. These threads are designed to meet specific requirements for durability and performance, making them popular choices for industries that demand robust and reliable stitching solutions.

Both Polyester sewing thread 30/2 and Polyester sewing thread 30/3 are widely used across various sectors due to their excellent balance of strength, flexibility, and cost-effectiveness. Their ability to withstand rigorous use and environmental exposure makes them ideal for applications where seam integrity is crucial.

Polyester sewing thread 30/2 and Polyester sewing thread 30/3 are extensively used in industries such as luggage, denim, footwear, and outdoor gear.

These sectors require threads that can withstand heavy use and exposure to harsh conditions without compromising seam integrity.

For example, in the manufacturing of backpacks and hiking boots, Polyester sewing thread 30/2 and Polyester sewing thread 30/3 provide the necessary durability and strength to ensure that the products remain functional and reliable over time.

In the denim industry, these threads are used to create seams that can endure frequent wear and washing. Their high abrasion resistance and tensile strength make them suitable for high-speed sewing machines, which is crucial for manufacturers aiming to maximize productivity while maintaining quality. Additionally, both threads offer excellent colorfastness and resistance to chemical degradation, ensuring that the seams remain intact and visually appealing over time.

-

Physical Characteristics

Physical CharacteristicsWear Resistance: Both Polyester sewing thread 30/2 and Polyester sewing thread 30/3 exhibit excellent abrasion resistance, making them suitable for applications that involve heavy use and exposure to the elements. However, Polyester sewing thread 30/3 has slightly higher abrasion resistance due to its thicker construction.

Strength: Polyester sewing thread 30/3 has a higher tensile strength compared to Polyester sewing thread 30/2, making it more suitable for heavier materials and thicker seams.

Elasticity: Polyester sewing thread 30/3 offers better elasticity, which allows it to stretch and recover without breaking. This property is particularly useful in applications that require flexibility, such as outdoor gear and footwear. -

Usage Scenarios

Usage ScenariosLightweight Applications: Polyester sewing thread 30/2 is often preferred for lighter-weight fabrics and delicate sewing tasks due to its finer texture. It is ideal for applications such as lightweight denim, thin leather, and delicate textiles.

Heavy-Duty Applications: Polyester sewing thread 30/3 is more suitable for heavier materials and thicker seams, making it a popular choice for heavy-duty outdoor gear, industrial products, and thick denim. Its robustness ensures that seams remain intact even under significant stress. -

Technical Parameters

Technical ParametersThread Thickness: Polyester sewing thread 30/2 has a tex size of 80, while Polyester sewing thread 30/3 has a tex size of 90. This difference in thickness affects the thread’s performance in various sewing scenarios.

Colorfastness: Both threads offer high colorfastness, ensuring that the seams remain visually appealing even after repeated washing and exposure to sunlight.

Thermal Stability: Both Polyester sewing thread 30/2 and Polyester sewing thread 30/3 are highly resistant to thermal degradation, making them suitable for applications that involve exposure to heat. -

Price and Cost-Effectiveness

Price and Cost-EffectivenessCost: Polyester sewing thread 30/2 is generally more affordable due to its finer texture and lower material usage. However, the choice between the two threads ultimately depends on the specific requirements of the application.

Value for Money: While Polyester sewing thread 30/2 may be more cost-effective for lighter-weight projects, Polyester sewing thread 30/3 offers superior strength and durability for heavier applications, making it a more cost-effective choice in the long run.

-

Konsultation

Der Anpassungsprozess beginnt mit einem ausführlichen Beratungsgespräch, in dem wir die spezifischen Bedürfnisse des Kunden erörtern, einschließlich Fadenstärke, Farbanforderungen und anwendungsspezifische Anforderungen. Unser Expertenteam arbeitet eng mit dem Kunden zusammen, um seine einzigartigen Anforderungen zu verstehen und Empfehlungen auszusprechen.

Der Anpassungsprozess beginnt mit einem ausführlichen Beratungsgespräch, in dem wir die spezifischen Bedürfnisse des Kunden erörtern, einschließlich Fadenstärke, Farbanforderungen und anwendungsspezifische Anforderungen. Unser Expertenteam arbeitet eng mit dem Kunden zusammen, um seine einzigartigen Anforderungen zu verstehen und Empfehlungen auszusprechen. -

Angebot

Sobald die Anforderungen klar definiert sind, erstellen wir ein detailliertes Angebot, in dem die Kosten, die Lieferfrist und andere relevante Details aufgeführt sind. Unsere Kostenvoranschläge sind transparent und umfassend, so dass die Kunden ein klares Verständnis der anfallenden Kosten haben.

Sobald die Anforderungen klar definiert sind, erstellen wir ein detailliertes Angebot, in dem die Kosten, die Lieferfrist und andere relevante Details aufgeführt sind. Unsere Kostenvoranschläge sind transparent und umfassend, so dass die Kunden ein klares Verständnis der anfallenden Kosten haben. -

Produktion

Unser Produktionsprozess ist hocheffizient und qualitätsorientiert und gewährleistet, dass die kundenspezifischen Gewinde den höchsten Anforderungen an Leistung und Haltbarkeit entsprechen. Wir verwenden hochmoderne Anlagen und strenge Qualitätskontrollmaßnahmen, um Gewinde herzustellen, die die Industriestandards übertreffen.

Unser Produktionsprozess ist hocheffizient und qualitätsorientiert und gewährleistet, dass die kundenspezifischen Gewinde den höchsten Anforderungen an Leistung und Haltbarkeit entsprechen. Wir verwenden hochmoderne Anlagen und strenge Qualitätskontrollmaßnahmen, um Gewinde herzustellen, die die Industriestandards übertreffen. -

Versand

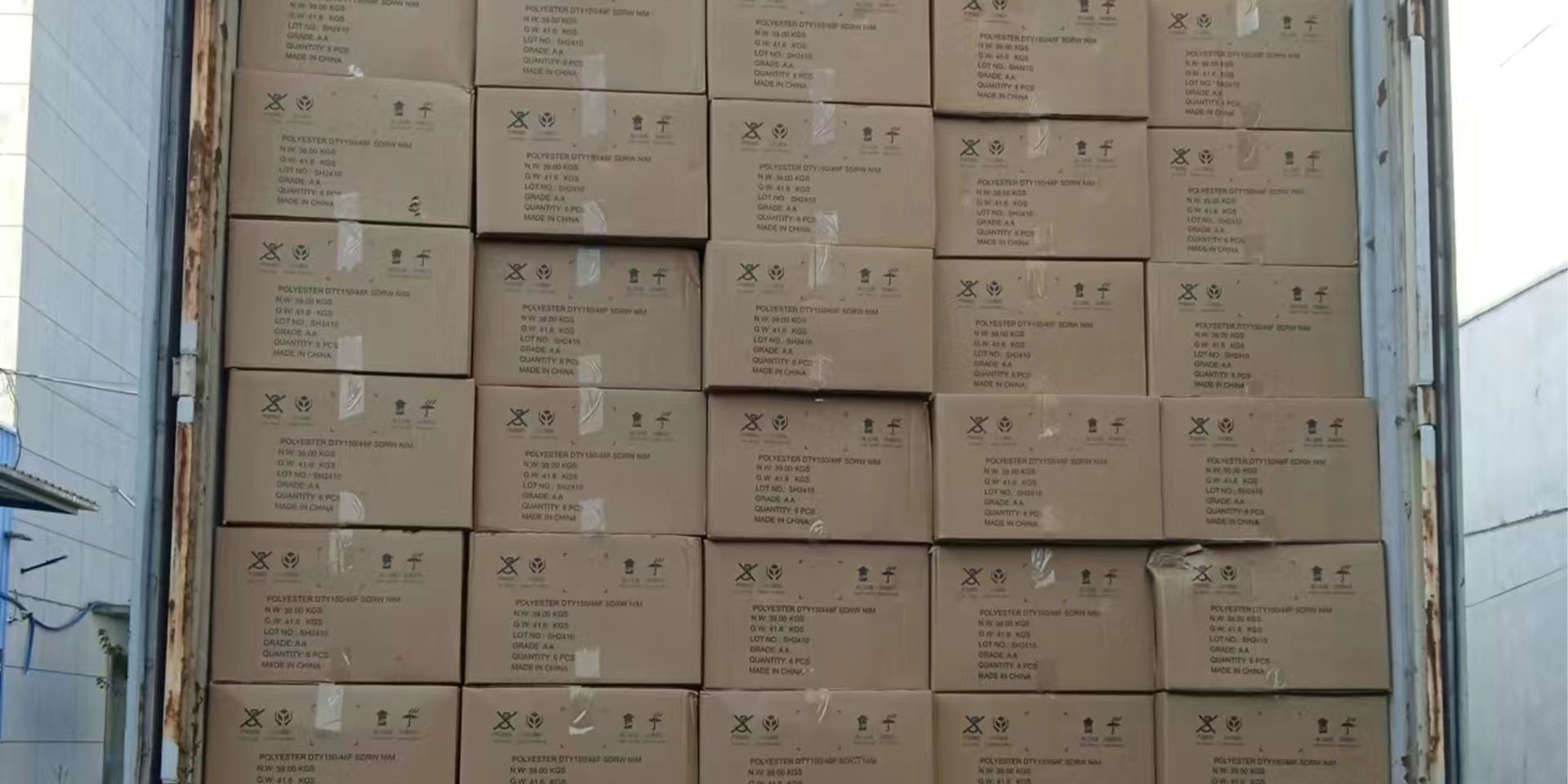

Nach der Produktion werden die maßgeschneiderten Fäden sorgfältig verpackt und innerhalb des vereinbarten Zeitrahmens an den Kunden versandt. Wir bieten zuverlässige Logistiklösungen, um sicherzustellen, dass die Fäden den Kunden umgehend und in einwandfreiem Zustand erreichen.

Nach der Produktion werden die maßgeschneiderten Fäden sorgfältig verpackt und innerhalb des vereinbarten Zeitrahmens an den Kunden versandt. Wir bieten zuverlässige Logistiklösungen, um sicherzustellen, dass die Fäden den Kunden umgehend und in einwandfreiem Zustand erreichen.

-

What is the specific fineness (such as yarn count) of Polyester sewing thread 30/2 and Polyester sewing thread 30/3? Can it be adjusted according to my needs?

The fineness of Polyester sewing thread 30/2 is 80 tex, while the fineness of Polyester sewing thread 30/3 is 90 tex. These two specifications are set according to international standards to meet the needs of different application scenarios. Although the standard specifications are already widely used in most industries, we can customize them according to your specific needs. For example, if you need a thinner or thicker thread, we can adjust the fineness, but the production cost and time need to be evaluated based on the customization amount and specific requirements.

-

The article mentioned that 30/3 has higher wear resistance and strength. How much higher can it be? Are there any relevant data or test results for reference?

Polyester sewing thread 30/3 is indeed better in wear resistance and strength than 30/2. Specifically, the tensile strength of 30/3 is about 15% higher than that of 30/2, and the wear resistance is improved by about 20%. These data are obtained through standard tensile tests and abrasion resistance tests. We can provide you with a detailed test report in the customized service to help you better understand the performance differences between the two threads.

-

My product is an outdoor mountaineering bag. Which one is more suitable, 30/2 or 30/3? If 30/2 is chosen, will the product quality be affected due to insufficient strength?

For outdoor mountaineering bags, we recommend using Polyester sewing thread 30/3 because it has higher strength and wear resistance, and can better cope with the friction and pulling that the mountaineering bag may encounter during use. Although 30/2 can also be used for lightweight outdoor products, for applications such as mountaineering bags that require high-strength sewing, 30/3 is a more suitable choice to ensure the durability and reliability of the product.

-

Ich benötige eine spezielle Farbe, kann der kundenspezifische Service diese erfüllen? Kann garantiert werden, dass die maßgeschneiderte Farbe genau mit dem von mir bereitgestellten Muster übereinstimmt?

Unser kundenspezifischer Service kann Ihre speziellen Farbwünsche erfüllen. Wir verwenden fortschrittliche Färbetechnologie und ein professionelles Farbabstimmungssystem, um sicherzustellen, dass die kundenspezifische Farbe in hohem Maße mit dem von Ihnen bereitgestellten Muster übereinstimmt. Vor der Produktion stellen wir Ihnen Muster zur Bestätigung zur Verfügung, um sicherzustellen, dass die Farbe Ihren Anforderungen entspricht. Falls erforderlich, können wir auch ein Farbmanagement gemäß Ihren Markenstandards durchführen, um die Farbstabilität jeder Charge zu gewährleisten.

-

The article mentions that 30/2 is more economical and 30/3 is more durable. Can you provide an approximate price range? If I purchase in large quantities, will there be a discount?

Polyester sewing thread 30/2 is usually slightly lower than 30/3, and the specific price will vary depending on factors such as order volume, customization requirements and delivery time. For large-volume purchases, we provide a flexible pricing strategy, and the larger the order volume, the lower the unit price. For example, when the order volume reaches a certain scale, we can provide a corresponding discount. The specific price and discount can be communicated with you in detail during the quotation stage.

-

Wie lange dauert es von der Bestellung bis zur Lieferung, wenn ich mich für einen individuellen Service entscheide? Kann die Lieferung beschleunigt werden?

Die Vorlaufzeit für kundenspezifische Dienstleistungen hängt normalerweise von der Komplexität der Anpassung und dem Auftragsvolumen ab. Im Allgemeinen dauert es 15-25 Arbeitstage von der Bestellung bis zur Lieferung. Wenn Ihr Projekt dringenden Bedarf hat, können wir Ihnen einen beschleunigten Service anbieten. Wir werden den Produktionsplan nach Ihren spezifischen Bedürfnissen ausrichten, um eine pünktliche Lieferung zu gewährleisten.

-

Wie sind die Qualitätsstandards dieser beiden Nähgarne? Gibt es entsprechende Zertifizierungen oder Prüfberichte?

Unsere Nähgarne folgen streng den internationalen Qualitätsstandards, einschließlich der Zertifizierung des Qualitätsmanagementsystems nach ISO 9001 und der Umweltzertifizierung nach OEKO-TEX Standard 100. Jede Charge von Produkten wird strengen Qualitätsprüfungen unterzogen, einschließlich Zugprüfung, Abriebfestigkeitsprüfung, Farbechtheitsprüfung, usw. Wir können auch detaillierte Prüfberichte nach Ihren Wünschen erstellen, um sicherzustellen, dass die von Ihnen verwendeten Nähgarne den höchsten Standards entsprechen.

-

The article mentions that 30/2 and 30/3 have good thermal stability. Can you specify their heat-resistant temperature range?

Polyester sewing thread 30/2 and 30/3 have excellent thermal stability. They can maintain stable performance at high temperatures of 150°C and can withstand higher temperatures for a short period of time. This thermal stability makes them very suitable for sewing processes that require high temperature treatment, such as ironing, hot pressing, etc. If you have higher heat resistance requirements, we can provide customized solutions based on specific application scenarios.

-

Meine Bestellmenge könnte relativ klein sein. Gibt es eine Mindestbestellmenge? Wirkt sich eine geringe Bestellmenge auf den Preis oder die Lieferzeit aus?

Da wir wissen, dass die Kunden unterschiedliche Bedürfnisse haben, versuchen wir, die Mindestbestellmenge zu reduzieren, um den Bedürfnissen der verschiedenen Kunden gerecht zu werden. Für Standardspezifikationen beträgt die Mindestbestellmenge 100 Kilogramm, für kundenspezifische Produkte ist die Mindestbestellmenge ein Container. Wenn Ihre Bestellmenge klein ist, werden wir trotzdem unser Bestes tun, um Ihre Anforderungen zu erfüllen, aber der Stückpreis kann entsprechend den Kosten für die Anpassung angepasst werden. Die Lieferzeit wird in der Regel durch kleine Bestellmengen nicht beeinträchtigt, und wir werden die Produktion und Lieferung gemäß den Standardverfahren organisieren.