Polyester Sewing Thread 40/2 and 40/3 are two popular specifications in the world of sewing threads, commonly used across various industries, including apparel, umbrellas, and home textiles. These threads are made from 100% polyester fibers, offering excellent strength, durability, resistance to shrinkage, and high color fastness. Ideal for a wide range of fabrics and sewing techniques, Polyester Sewing Thread 40/2 and 40/3 are perfect choices for both industrial sewing and handcrafts.

The main difference between Polyester Sewing Thread 40/2 and 40/3 lies in the thickness and strength of the threads. 40/3 is more suitable for heavier fabrics, while 40/2 is perfect for medium-weight materials. This distinction allows users to choose the appropriate thread based on the fabric’s weight and sewing requirements, ensuring optimal results in various applications.

-

Apparel Manufacturing: Polyester Sewing Thread 40/2 and 40/3 are ideal for the production of various types of clothing, such as shirts, jackets, and denim jeans. These threads offer excellent sewing performance, allowing them to be used on high-speed sewing machines while maintaining the aesthetic appearance and durability of the seams. Their robust characteristics ensure that the finished garments remain strong and long-lasting, even after repeated washing and wear.

-

Umbrella Production: One of the standout features of Polyester Sewing Thread 40/2 and 40/3 is their resistance to water and ultraviolet (UV) rays, making them the perfect choice for umbrella manufacturing. The threads can withstand the stresses and wear that umbrellas face in harsh weather conditions, ensuring the seams remain intact and functional for an extended period of time. Polyester’s inherent resistance to moisture and UV degradation guarantees that umbrellas sewn with these threads remain durable and aesthetically pleasing.

-

Home Textiles: Polyester Sewing Thread 40/2 and 40/3 are also commonly used in home textiles, such as curtains, bed linens, and sofa covers. These threads provide outstanding durability and color retention, even when subjected to daily use and regular washing. The threads’ ability to maintain their strength and color vibrancy makes them a perfect choice for items that require longevity and resilience in high-traffic areas of the home.

-

Other Uses: In addition to their use in apparel, umbrellas, and home textiles, Polyester Sewing Thread 40/2 and 40/3 are versatile enough to be applied in various other industries, such as crafting and outdoor products. From handmade accessories to tents and outdoor gear, these threads demonstrate their adaptability and ability to perform well in different conditions. Whether used in light or heavy-duty projects, Polyester Sewing Thread 40/2 and 40/3 deliver consistent results.

-

Durability

DurabilityPolyester threads are known for their high abrasion resistance, ensuring that sewn products last longer without showing signs of wear. This durability is essential for items that are exposed to frequent friction, such as clothing, upholstery, and outdoor gear.

-

Color Fastness

Color FastnessPolyester Sewing Thread 40/2 and 40/3 boast excellent color retention, which is particularly important for items like apparel and home textiles that are washed frequently. The threads’ ability to retain their color over time ensures that the products remain aesthetically pleasing and vibrant.

-

Chemical Resistance

Chemical ResistancePolyester is inherently resistant to a wide range of chemicals, making these threads suitable for use in various environments, including those exposed to detergents, oils, and other industrial substances. This feature ensures the longevity and reliability of the sewn items in a variety of conditions.

-

Heat Resistance

Heat ResistancePolyester threads are also resistant to high temperatures, making them ideal for applications where heat exposure is a concern, such as sewing for industrial or automotive products. This heat resistance prevents the threads from melting or degrading under heat stress.

-

Konsultation

Der Anpassungsprozess beginnt mit einem ausführlichen Beratungsgespräch, in dem wir die spezifischen Bedürfnisse des Kunden erörtern, einschließlich Fadenstärke, Farbanforderungen und anwendungsspezifische Anforderungen. Unser Expertenteam arbeitet eng mit dem Kunden zusammen, um seine einzigartigen Anforderungen zu verstehen und Empfehlungen auszusprechen.

Der Anpassungsprozess beginnt mit einem ausführlichen Beratungsgespräch, in dem wir die spezifischen Bedürfnisse des Kunden erörtern, einschließlich Fadenstärke, Farbanforderungen und anwendungsspezifische Anforderungen. Unser Expertenteam arbeitet eng mit dem Kunden zusammen, um seine einzigartigen Anforderungen zu verstehen und Empfehlungen auszusprechen. -

Angebot

Sobald die Anforderungen klar definiert sind, erstellen wir ein detailliertes Angebot, in dem die Kosten, die Lieferfrist und andere relevante Details aufgeführt sind. Unsere Kostenvoranschläge sind transparent und umfassend, so dass die Kunden ein klares Verständnis der anfallenden Kosten haben.

Sobald die Anforderungen klar definiert sind, erstellen wir ein detailliertes Angebot, in dem die Kosten, die Lieferfrist und andere relevante Details aufgeführt sind. Unsere Kostenvoranschläge sind transparent und umfassend, so dass die Kunden ein klares Verständnis der anfallenden Kosten haben. -

Produktion

Unser Produktionsprozess ist hocheffizient und qualitätsorientiert und gewährleistet, dass die kundenspezifischen Gewinde den höchsten Anforderungen an Leistung und Haltbarkeit entsprechen. Wir verwenden hochmoderne Anlagen und strenge Qualitätskontrollmaßnahmen, um Gewinde herzustellen, die die Industriestandards übertreffen.

Unser Produktionsprozess ist hocheffizient und qualitätsorientiert und gewährleistet, dass die kundenspezifischen Gewinde den höchsten Anforderungen an Leistung und Haltbarkeit entsprechen. Wir verwenden hochmoderne Anlagen und strenge Qualitätskontrollmaßnahmen, um Gewinde herzustellen, die die Industriestandards übertreffen. -

Versand

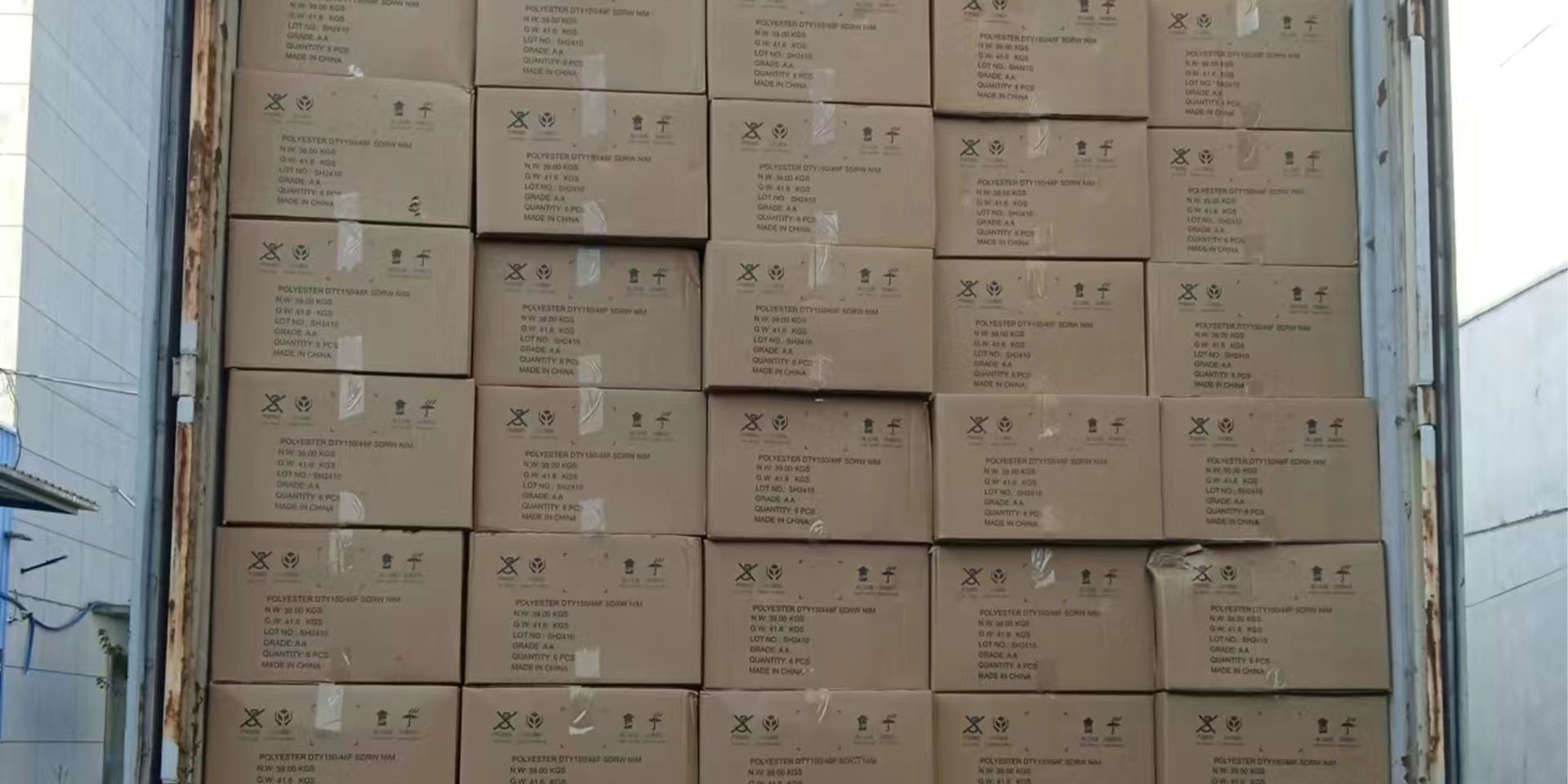

Nach der Produktion werden die maßgeschneiderten Fäden sorgfältig verpackt und innerhalb des vereinbarten Zeitrahmens an den Kunden versandt. Wir bieten zuverlässige Logistiklösungen, um sicherzustellen, dass die Fäden den Kunden umgehend und in einwandfreiem Zustand erreichen.

Nach der Produktion werden die maßgeschneiderten Fäden sorgfältig verpackt und innerhalb des vereinbarten Zeitrahmens an den Kunden versandt. Wir bieten zuverlässige Logistiklösungen, um sicherzustellen, dass die Fäden den Kunden umgehend und in einwandfreiem Zustand erreichen.

-

What is the main difference between Polyester Sewing Thread 40/2 and 40/3?

The main difference between 40/2 and 40/3 is the thickness and strength of the thread. 40/3 is more suitable for thicker fabrics, while 40/2 is suitable for medium-thick fabrics.

-

What types of fabrics are suitable for these two wires?

What types of fabrics are suitable for these two wires? 40/2 is suitable for medium-thick fabrics, such as shirts, jackets, etc.; 40/3 is suitable for thicker fabrics, such as denim, tents, etc.

-

How durable are Polyester Sewing Thread 40/2 and 40/3?

Both threads are made of 100% polyester fiber, which has the characteristics of high strength, abrasion resistance, shrinkage resistance and high color fastness, ensuring the long-term durability of the sewing thread.

-

I need a special color, can the customized service meet it? Can the customized color be guaranteed to be exactly the same as the sample I provided?

Our customized service can meet your special color needs. We use advanced dyeing technology and professional color matching system to ensure that the customized color is highly consistent with the sample you provide. Before production, we will provide samples for your confirmation to ensure that the color meets your requirements. If necessary, we can also perform color management according to your brand standards to ensure the color stability of each batch.

-

What are the color options for these threads?

Polyester Sewing Thread 40/2 and 40/3 are available in a variety of colors, and customers can customize the color as needed to meet different design requirements.

-

Wie lange dauert es von der Bestellung bis zur Lieferung, wenn ich mich für einen individuellen Service entscheide? Kann die Lieferung beschleunigt werden?

Die Vorlaufzeit für kundenspezifische Dienstleistungen hängt normalerweise von der Komplexität der Anpassung und dem Auftragsvolumen ab. Im Allgemeinen dauert es 15-25 Arbeitstage von der Bestellung bis zur Lieferung. Wenn Ihr Projekt dringenden Bedarf hat, können wir Ihnen einen beschleunigten Service anbieten. Wir werden den Produktionsplan nach Ihren spezifischen Bedürfnissen ausrichten, um eine pünktliche Lieferung zu gewährleisten.

-

Wie sind die Qualitätsstandards dieser beiden Nähgarne? Gibt es entsprechende Zertifizierungen oder Prüfberichte?

Unsere Nähgarne folgen streng den internationalen Qualitätsstandards, einschließlich der Zertifizierung des Qualitätsmanagementsystems nach ISO 9001 und der Umweltzertifizierung nach OEKO-TEX Standard 100. Jede Charge von Produkten wird strengen Qualitätsprüfungen unterzogen, einschließlich Zugprüfung, Abriebfestigkeitsprüfung, Farbechtheitsprüfung, usw. Wir können auch detaillierte Prüfberichte nach Ihren Wünschen erstellen, um sicherzustellen, dass die von Ihnen verwendeten Nähgarne den höchsten Standards entsprechen.

-

Stellen Sie Proben für Tests zur Verfügung?

Viele Anbieter stellen ihren Kunden kostenlose Muster zum Testen zur Verfügung, aber die Kunden müssen möglicherweise für den Versand bezahlen. Es wird empfohlen, sich vor einer Bestellung beim Anbieter über die Musterpolitik zu informieren.

-

Meine Bestellmenge könnte relativ klein sein. Gibt es eine Mindestbestellmenge? Wirkt sich eine geringe Bestellmenge auf den Preis oder die Lieferzeit aus?

Da wir wissen, dass die Kunden unterschiedliche Bedürfnisse haben, versuchen wir, die Mindestbestellmenge zu reduzieren, um den Bedürfnissen der verschiedenen Kunden gerecht zu werden. Für Standardspezifikationen beträgt die Mindestbestellmenge 100 Kilogramm, für kundenspezifische Produkte ist die Mindestbestellmenge ein Container. Wenn Ihre Bestellmenge klein ist, werden wir trotzdem unser Bestes tun, um Ihre Anforderungen zu erfüllen, aber der Stückpreis kann entsprechend den Kosten für die Anpassung angepasst werden. Die Lieferzeit wird in der Regel durch kleine Bestellmengen nicht beeinträchtigt, und wir werden die Produktion und Lieferung gemäß den Standardverfahren organisieren.