In early 2025, federal policy discussions on industrial textiles have focused on Polyester Spun Yarn. The government is evaluating regulations to enhance sustainability and safety in textile manufacturing. This policy evolution aims to balance environmental protection with industry needs, potentially encouraging wider adoption of Polyester Spun Yarn in the textile industry.

As global attention increasingly shifts toward sustainable manufacturing, materials like benang pintal poliester are finding renewed relevance. While many industries face growing regulatory challenges, especially concerning plastic waste and non-renewable inputs, the textile sector has unique opportunities to adapt and innovate. Companies such as textilessupplychain (https://www.textilessupplychain.com/) are leading the charge in balancing performance, durability, and environmental responsibility in yarn production.

Although recent policy changes—particularly in plastic and packaging—have created uncertainty across sectors, they also emphasize the urgency of transitioning toward materials that support circular economy models. In this evolving context, benang pintal poliester continues to be a dependable, versatile solution that can align with both environmental goals and consumer demand.

State and Regional Sustainability Policies: Textile Implications

Many U.S. states have embraced proactive environmental legislation—such as New York’s Packaging Reduction Act and California’s bans on EPS packaging—to reduce plastic dependency and improve material recovery. While these laws primarily target plastic foodware and packaging, their implications extend to related sectors, including textiles.

Manufacturers of benang pintal poliester—particularly those integrating recycled PET or pursuing low-emission production processes—are well-positioned to align with these eco-driven trends. Benang pintal poliester, made from staple fibers, is increasingly seen as a responsible alternative when it incorporates recycled content and complies with eco-certifications.

These developments offer textile businesses the opportunity to anticipate market shifts, optimize material sourcing, and participate in sustainable initiatives that state governments are rapidly adopting.

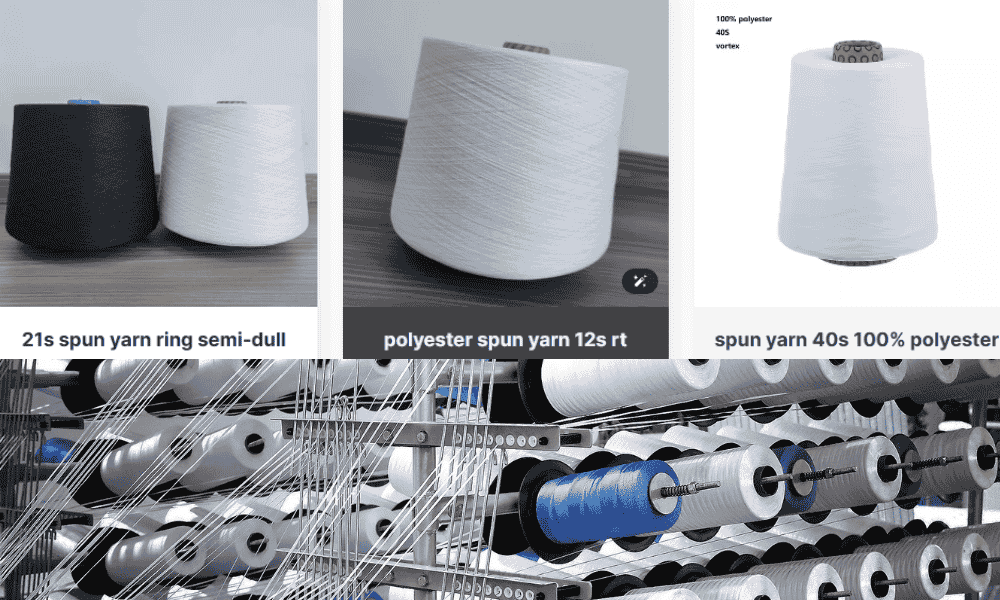

Environmentally friendly Polyerster spun yarn

Global Approaches to Sustainable Materials and Their Relevance to Yarn

Global regulatory movements—such as the EU’s Single-Use Plastics Directive and Canada’s national plastics ban—demonstrate the potential of cohesive sustainability strategies. For textile manufacturers, these models provide a roadmap for integrating sustainability into core business operations.

Internationally, recycled and eco-friendly benang pintal poliester products are already being embraced for their reduced environmental footprint. The versatility of benang pintal poliester allows it to be used in a variety of applications—from apparel and home furnishings to industrial fabrics—making it an adaptable choice for companies aligning with emerging global standards.

Eco-Innovation in Yarn Production: Rising to the Challenge

To stay competitive in this changing regulatory environment, companies must invest in cleaner, more transparent production practices. For producers of benang pintal poliester, this means:

-

Sourcing post-consumer or post-industrial polyester waste as feedstock

-

Reducing energy consumption in the spinning process

-

Ensuring compliance with certifications like GRS (Global Recycled Standard) and OEKO-TEX

-

Improving product traceability through digital supply chain integration

By focusing on these strategies, benang pintal poliester manufacturers can enhance their environmental credibility and appeal to environmentally conscious buyers.

At textilessupplychain, we are committed to helping clients access yarn products that meet evolving sustainability benchmarks—without compromising on strength, softness, or affordability.

Benang pintal poliester

The Business Case for Sustainable Yarn Solutions

The shift toward greener materials isn’t just a policy-driven trend—it’s becoming an economic imperative. Companies that adapt quickly to changing market expectations for environmentally responsible materials often enjoy:

-

Increased access to government and institutional procurement contracts

-

Enhanced brand reputation and consumer loyalty

-

Risk mitigation against future regulatory changes or restrictions

-

Greater flexibility in international trade and export compliance

In this context, polyester yarn stands out as a material that can meet durability requirements while being tailored to various environmental performance levels. This makes it ideal for both mass-market products and high-spec applications.

Consumer Awareness and Demand for Transparency

As consumers become more informed, their preferences are shifting toward materials that demonstrate traceable, responsible production. This presents a compelling incentive for brands to use benang pintal poliester that comes from certified or recycled sources.

Brands can differentiate themselves by clearly communicating:

-

The recycled content percentage in their yarns

-

The environmental benefits of benang pintal poliester over alternatives

-

How the product lifecycle contributes to reduced environmental impact

Transparency in sourcing and sustainability claims will become a core part of consumer trust and brand loyalty—especially in apparel, footwear, and interiors.

Technological Advancement and Future Potential

Innovation continues to expand the potential of benang pintal poliester in sustainable manufacturing. Advances in low-temperature dyeing, waterless finishing, and microplastic capture are helping yarn producers reduce their environmental impact even further.

In addition, emerging partnerships between universities, material scientists, and industry leaders are producing enhanced benang pintal poliester that:

-

Offers improved biodegradability when blended with specific natural fibers

-

Is engineered to minimize microplastic shedding

-

Can be fully recycled through closed-loop textile recovery systems

These breakthroughs are making it easier for textile companies to meet both regulatory expectations and environmental goals.

High quality Polyerster spun yarn

A Path Forward with Purpose

In a world where environmental policies are rapidly evolving and public expectations for sustainability are growing, benang pintal poliester offers a viable and responsible path forward. Whether crafted from virgin or recycled polyester, it provides the functionality and durability that global markets demand—while increasingly supporting green innovation and resource efficiency.

At textilessupplychain, we believe that progress in textiles must align with ecological responsibility. By choosing benang pintal poliester solutions that are thoughtfully sourced and sustainably produced, businesses can position themselves not just to survive policy changes—but to thrive in a cleaner, smarter future. Let us be your partner in building a textile supply chain that prioritizes performance, compliance, and long-term environmental stewardship.

Visit us at: https://www.textilessupplychain.com

Explore more about our high-quality, sustainable polyester spun yarn offerings.

Berita Sebelumnya

What Makes Polyester Spun Yarn the Top Choice f...Berita Berikutnya

Polyester POY and Policy Shifts: Navigating Sus...

Oleh Benang

Produk Fitur

-

Benang Poliester DTY 100D / 144F

Benang Poliester DTY 100D / 144FBenang Poliester DTY 100D/144F: Panduan Utama untuk ...

-

Benang Poliester DTY 100D / 96F

Benang Poliester DTY 100D / 96FBenang Poliester DTY 100D/96F: Benang Poliester yang Lembut dan Stabil ...

-

Benang Poliester DTY 75D / 144F SIM

Benang Poliester DTY 75D / 144F SIMBenang Poliester DTY 75D/144F SIM: Pilihan Utama untuk ...