Polyester sewing thread is an essential component in various industries, including textile, garment manufacturing, and industrial product assembly. Its high strength, durability, and versatility make it indispensable for creating long-lasting seams in a wide range of applications.

Among the diverse polyester sewing threads available, Polyester sewing thread 30/2 and Polyester sewing thread 30/3 hold significant positions in the market. These threads are designed to meet specific requirements for durability and performance, making them popular choices for industries that demand robust and reliable stitching solutions.

Both Polyester sewing thread 30/2 and Polyester sewing thread 30/3 are widely used across various sectors due to their excellent balance of strength, flexibility, and cost-effectiveness. Their ability to withstand rigorous use and environmental exposure makes them ideal for applications where seam integrity is crucial.

Polyester sewing thread 30/2 and Polyester sewing thread 30/3 are extensively used in industries such as luggage, denim, footwear, and outdoor gear.

These sectors require threads that can withstand heavy use and exposure to harsh conditions without compromising seam integrity.

For example, in the manufacturing of backpacks and hiking boots, Polyester sewing thread 30/2 and Polyester sewing thread 30/3 provide the necessary durability and strength to ensure that the products remain functional and reliable over time.

In the denim industry, these threads are used to create seams that can endure frequent wear and washing. Their high abrasion resistance and tensile strength make them suitable for high-speed sewing machines, which is crucial for manufacturers aiming to maximize productivity while maintaining quality. Additionally, both threads offer excellent colorfastness and resistance to chemical degradation, ensuring that the seams remain intact and visually appealing over time.

-

Physical Characteristics

Physical CharacteristicsWear Resistance: Both Polyester sewing thread 30/2 and Polyester sewing thread 30/3 exhibit excellent abrasion resistance, making them suitable for applications that involve heavy use and exposure to the elements. However, Polyester sewing thread 30/3 has slightly higher abrasion resistance due to its thicker construction.

Strength: Polyester sewing thread 30/3 has a higher tensile strength compared to Polyester sewing thread 30/2, making it more suitable for heavier materials and thicker seams.

Elasticity: Polyester sewing thread 30/3 offers better elasticity, which allows it to stretch and recover without breaking. This property is particularly useful in applications that require flexibility, such as outdoor gear and footwear. -

Usage Scenarios

Usage ScenariosLightweight Applications: Polyester sewing thread 30/2 is often preferred for lighter-weight fabrics and delicate sewing tasks due to its finer texture. It is ideal for applications such as lightweight denim, thin leather, and delicate textiles.

Heavy-Duty Applications: Polyester sewing thread 30/3 is more suitable for heavier materials and thicker seams, making it a popular choice for heavy-duty outdoor gear, industrial products, and thick denim. Its robustness ensures that seams remain intact even under significant stress. -

Technical Parameters

Technical ParametersThread Thickness: Polyester sewing thread 30/2 has a tex size of 80, while Polyester sewing thread 30/3 has a tex size of 90. This difference in thickness affects the thread’s performance in various sewing scenarios.

Colorfastness: Both threads offer high colorfastness, ensuring that the seams remain visually appealing even after repeated washing and exposure to sunlight.

Thermal Stability: Both Polyester sewing thread 30/2 and Polyester sewing thread 30/3 are highly resistant to thermal degradation, making them suitable for applications that involve exposure to heat. -

Price and Cost-Effectiveness

Price and Cost-EffectivenessCost: Polyester sewing thread 30/2 is generally more affordable due to its finer texture and lower material usage. However, the choice between the two threads ultimately depends on the specific requirements of the application.

Value for Money: While Polyester sewing thread 30/2 may be more cost-effective for lighter-weight projects, Polyester sewing thread 30/3 offers superior strength and durability for heavier applications, making it a more cost-effective choice in the long run.

-

コンサルテーション

カスタマイズ・プロセスは詳細なコンサルテーションから始まり、糸の太さ、色の要件、用途特有の要求など、お客様固有のニーズについて話し合います。私たちの専門家チームはお客様と緊密に連携し、お客様独自の要件を理解し、ご提案します。

カスタマイズ・プロセスは詳細なコンサルテーションから始まり、糸の太さ、色の要件、用途特有の要求など、お客様固有のニーズについて話し合います。私たちの専門家チームはお客様と緊密に連携し、お客様独自の要件を理解し、ご提案します。 -

引用

要件が明確に定義された後、費用、納期、その他の関連する詳細を概説した詳細な見積書を提供します。当社の見積書は透明性が高く、包括的であるため、お客様は関連するコストを明確に理解することができます。

要件が明確に定義された後、費用、納期、その他の関連する詳細を概説した詳細な見積書を提供します。当社の見積書は透明性が高く、包括的であるため、お客様は関連するコストを明確に理解することができます。 -

製造

当社の生産工程は非常に効率的で品質に重点を置いており、カスタマイズされたスレッドが最高水準の性能と耐久性を満たすことを保証します。最先端の設備と厳格な品質管理措置を用いて、業界標準を上回る糸を生産しています。

当社の生産工程は非常に効率的で品質に重点を置いており、カスタマイズされたスレッドが最高水準の性能と耐久性を満たすことを保証します。最先端の設備と厳格な品質管理措置を用いて、業界標準を上回る糸を生産しています。 -

送料

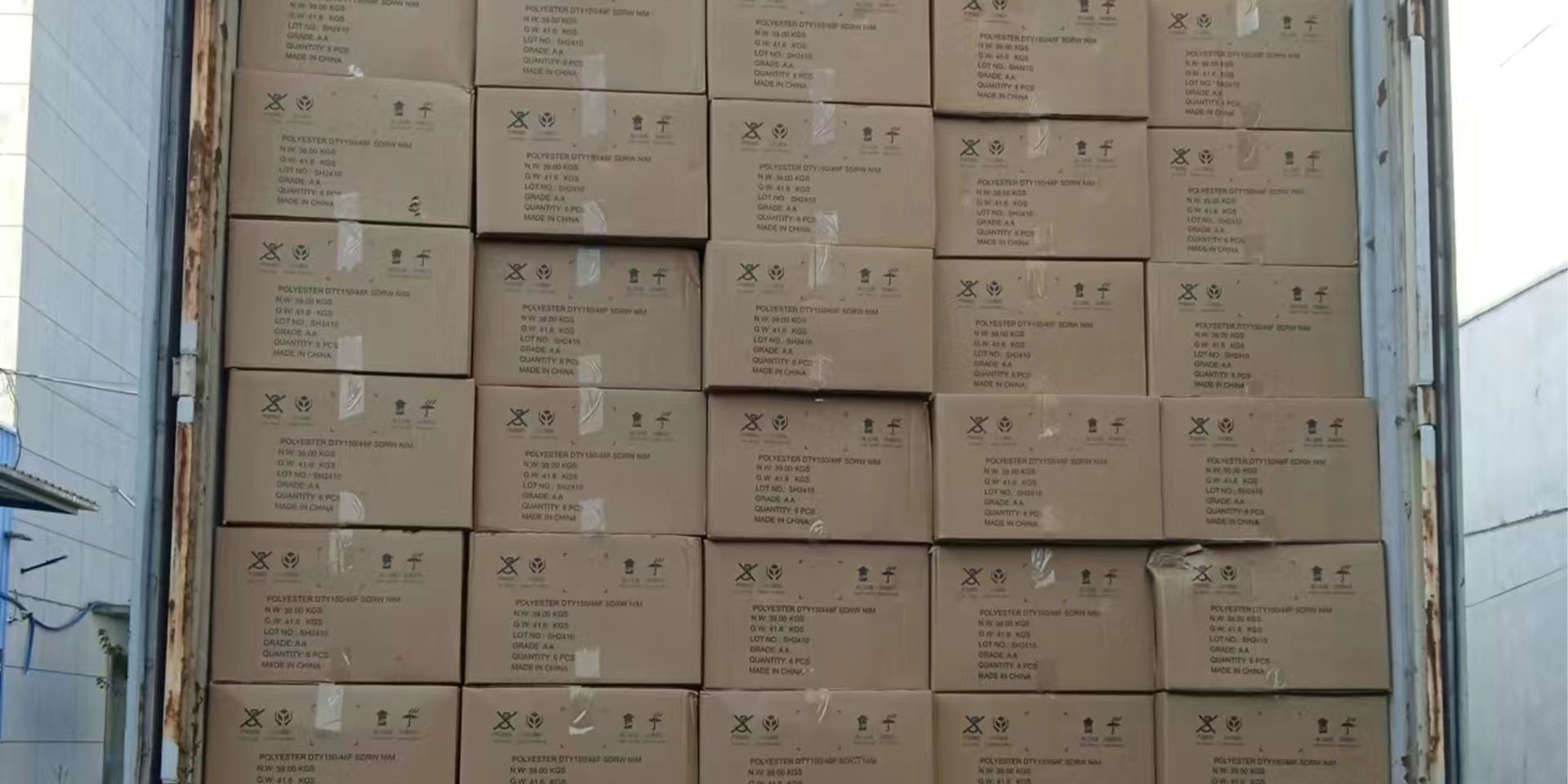

生産後、カスタマイズされた糸は慎重に梱包され、合意された時間枠内でクライアントに出荷されます。糸が完璧な状態で迅速にお客様のお手元に届くよう、信頼性の高い物流ソリューションを提供しています。

生産後、カスタマイズされた糸は慎重に梱包され、合意された時間枠内でクライアントに出荷されます。糸が完璧な状態で迅速にお客様のお手元に届くよう、信頼性の高い物流ソリューションを提供しています。

-

What is the specific fineness (such as yarn count) of Polyester sewing thread 30/2 and Polyester sewing thread 30/3? Can it be adjusted according to my needs?

The fineness of Polyester sewing thread 30/2 is 80 tex, while the fineness of Polyester sewing thread 30/3 is 90 tex. These two specifications are set according to international standards to meet the needs of different application scenarios. Although the standard specifications are already widely used in most industries, we can customize them according to your specific needs. For example, if you need a thinner or thicker thread, we can adjust the fineness, but the production cost and time need to be evaluated based on the customization amount and specific requirements.

-

The article mentioned that 30/3 has higher wear resistance and strength. How much higher can it be? Are there any relevant data or test results for reference?

Polyester sewing thread 30/3 is indeed better in wear resistance and strength than 30/2. Specifically, the tensile strength of 30/3 is about 15% higher than that of 30/2, and the wear resistance is improved by about 20%. These data are obtained through standard tensile tests and abrasion resistance tests. We can provide you with a detailed test report in the customized service to help you better understand the performance differences between the two threads.

-

My product is an outdoor mountaineering bag. Which one is more suitable, 30/2 or 30/3? If 30/2 is chosen, will the product quality be affected due to insufficient strength?

For outdoor mountaineering bags, we recommend using Polyester sewing thread 30/3 because it has higher strength and wear resistance, and can better cope with the friction and pulling that the mountaineering bag may encounter during use. Although 30/2 can also be used for lightweight outdoor products, for applications such as mountaineering bags that require high-strength sewing, 30/3 is a more suitable choice to ensure the durability and reliability of the product.

-

特別な色が必要なのですが、カスタマイズサービスで対応できますか?カスタマイズされた色は、私が提供したサンプルと全く同じであることを保証できますか?

私たちのカスタマイズサービスは、あなたの特別な色のニーズを満たすことができます。高度な染色技術と専門的なカラーマッチングシステムを使用し、カスタマイズされた色が提供されたサンプルと非常に一致することを保証します。生産前に、サンプルを提供し、色がお客様の要求を満たすことを確認します。必要に応じて、お客様のブランド基準に従ってカラーマネージメントを行い、各バッチの色の安定性を確保することもできます。

-

The article mentions that 30/2 is more economical and 30/3 is more durable. Can you provide an approximate price range? If I purchase in large quantities, will there be a discount?

Polyester sewing thread 30/2 is usually slightly lower than 30/3, and the specific price will vary depending on factors such as order volume, customization requirements and delivery time. For large-volume purchases, we provide a flexible pricing strategy, and the larger the order volume, the lower the unit price. For example, when the order volume reaches a certain scale, we can provide a corresponding discount. The specific price and discount can be communicated with you in detail during the quotation stage.

-

カスタムサービスを選択した場合、注文から納品までどのくらいかかりますか?迅速な対応は可能ですか?

カスタムサービスのリードタイムは通常、カスタマイズの複雑さと注文量によって異なります。一般的には、ご注文から納品まで15~25営業日かかります。お客様のプロジェクトに緊急のニーズがある場合は、迅速なサービスを提供することができます。お客様の特定のニーズに応じて生産計画をアレンジし、納期厳守をお約束します。

-

この2つの縫製糸の品質基準は何ですか?関連する認証や試験報告書はありますか?

当社の縫製糸は、ISO 9001品質マネジメントシステム認証やエコテックス規格100環境認証など、国際的な品質基準に厳格に従っています。製品の各バッチは、引張試験、耐摩耗性試験、色堅牢度試験などの厳しい品質試験を受けます。また、お客様のニーズに応じて詳細な試験報告書を提供し、お客様が使用する縫製糸が最高基準を満たしていることを保証します。

-

The article mentions that 30/2 and 30/3 have good thermal stability. Can you specify their heat-resistant temperature range?

Polyester sewing thread 30/2 and 30/3 have excellent thermal stability. They can maintain stable performance at high temperatures of 150°C and can withstand higher temperatures for a short period of time. This thermal stability makes them very suitable for sewing processes that require high temperature treatment, such as ironing, hot pressing, etc. If you have higher heat resistance requirements, we can provide customized solutions based on specific application scenarios.

-

私の注文数量は比較的少ないかもしれません。最低注文数量の規定はありますか?注文数量が少ない場合、価格や納期に影響はありますか?

私たちは、お客様のニーズが多様であることを理解していますので、さまざまなお客様のニーズにお応えするために、最小注文数量を減らすようにしています。標準仕様の場合、最低注文数量は100キログラム、カスタマイズ製品の場合、最低注文数量は1コンテナです。ご注文数量が少ない場合でも、お客様のニーズにお応えできるよう最善を尽くしますが、カスタマイズ費用によって単価が調整される場合があります。通常、納期は少量の注文でも影響を受けず、標準的な手順に従って生産と配送を手配します。