Discover the strength and versatility of Polyester Spun Yarn. Ideal for clothing, home textiles, and industrial uses, it offers durability, colorfastness, and easy care. Enhance your textile projects with high-quality polyester spun yarn.

In the ever-evolving world of textiles, one material stands out for its unmatched versatility, durability, and cost-effectiveness — Gesponnen polyester garen. This widely used yarn has become a staple in both fashion and industrial applications, offering numerous advantages over traditional materials. From its production process to its environmental implications, Gesponnen polyester garen continues to set benchmarks in the textile industry. Below, we explore why it remains the top choice for creating quality fabrics across the globe.

The Composition and Manufacturing Process of Polyester Spun Yarn

Gesponnen polyester garen is created by spinning short polyester fibers into yarn using a mechanical process similar to that used for cotton. These fibers are first melted and extruded through spinnerets, cooled, and then cut into staple-length fibers. Afterward, they are spun into yarns, often blended with other fibers such as cotton or viscose to enhance comfort and breathability.

What makes Spun polyester particularly useful is that it mimics the properties of natural fibers while offering the durability of synthetic materials. The process allows manufacturers to control yarn strength, elasticity, and even texture, making it adaptable for various end uses. Whether it’s for apparel or industrial textiles, this method ensures consistency and scalability, making Gesponnen polyester garen a production favorite.

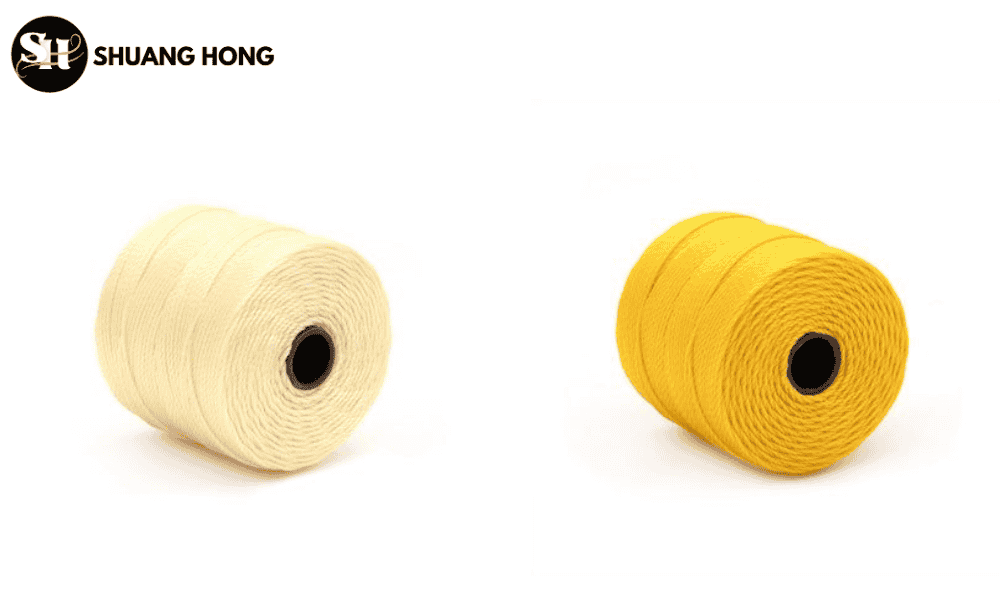

Gesponnen polyester garen

Key Advantages of Polyes

er Spun Yarn in Textile Applications

The benefits of Gesponnen polyester garen extend far beyond just its manufacturing convenience. It is cost-effective, making it accessible to a wide range of industries without sacrificing quality. Unlike natural fibers that may degrade or shrink over time, spun polyester offers long-lasting performance with excellent shape retention.

Additionally, it has high resistance to wrinkles, stains, and abrasions, making it ideal for both kleding en durable textiles. For manufacturers looking to meet tight deadlines and strict quality standards, Polyester garen presents a highly dependable option.

Another important benefit is color retention. Spun polyester absorbs dye well and maintains vibrant colors even after repeated washes, a major advantage for quality fabrics that require visual appeal over time.

How Polyester Spun Yarn Enhances Fabric Durability and Strength

One of the primary reasons for the popularity of Gesponnen polyester garen is its ability to significantly enhance fabric strength and overall durability. Unlike natural fibers like cotton, which can weaken when wet or exposed to UV light, polyestergaren retains its tensile strength under challenging conditions.

This makes it perfect for workwear, outdoor gear, uniforms, and other high-stress fabric applications. In many cases, yarn comparison studies have shown that spun polyester outperforms cotton, wool, and even some nylon blends when it comes to resistance against wear and tear.

Thanks to its molecular structure, Gesponnen polyester garen resists stretching, shrinking, and pilling. The result is a fabric that holds its shape and form much longer, which translates to better longevity and less frequent replacements—another mark of durable textiles.

Cost Efficiency and Production Benefits of Using Spun Polyester Yarn

When it comes to production economics, Gesponnen polyester garen presents a highly attractive option. First, it offers consistent quality with fewer defects during weaving or knitting, which reduces waste. Its fast dyeing ability and compatibility with high-speed machines make it ideal for mass production.

In terms of cost-effective yarn choices, spun polyester provides substantial value. It is cheaper to produce and purchase than many natural alternatives, yet delivers performance that often exceeds expectations.

Moreover, the availability of spun polyester in a variety of counts and textures means it can be customized for different products without the need for expensive modifications in machinery. This versatility keeps operational costs low and margins high, especially in competitive markets.

Polyester Spun Yarn’s Role in Sustainable Fabric Solutions

While polyester has often faced criticism for its environmental impact, advancements in recycling and eco-friendly manufacturing have significantly improved its profile. Gesponnen polyester garen can now be made from post-consumer plastic bottles and recycled polyester fibers, offering a second life to waste materials.

This contributes to reducing landfill loads and energy consumption during production. By blending recycled spun polyester with other biodegradable fibers, manufacturers are able to create hybrid fabrics that are both sustainable and high-performance.

In the context of sustainable textiles, Gesponnen polyester garen plays a crucial role. Its long life cycle, coupled with low water and energy requirements during washing and drying, helps reduce the environmental footprint of finished garments.

Spun yarn advantages

Ideal Applications: From Garments to Industrial Textiles

The applications of Gesponnen polyester garen are incredibly diverse. In the fashion industry, it’s used in everything from T-shirts and dresses to linings and outerwear. Its ability to blend seamlessly with cotton, viscose, or wool adds to its appeal in both casual and formal wear.

In industrial settings, spun polyester is used in the production of filtration fabrics, conveyor belts, and insulation materials. It’s also widely used in home furnishings such as curtains, upholstery, and bed linens.

For those interested in spun yarn applications, the adaptability of Gesponnen polyester garen is unmatched. It handles high temperatures, chemical exposure, and mechanical stress better than many other yarn types, making it indispensable in multiple fields.

Why Designers and Manufacturers Prefer Polyester Spun Yarn

Designers appreciate Gesponnen polyester garen for its wide design latitude. It can be engineered to imitate the sheen of silk or the softness of cotton, depending on the desired effect. Its excellent dye affinity allows for bold and consistent colorways, making it a go-to for fashion collections and branded apparel.

For manufacturers, the reliability of spun polyester reduces downtime and ensures higher throughput. Its uniformity across lots means less variation in production runs, which is critical for maintaining quality standards in mass production.

In the competitive world of textiles, having a reliable and versatile yarn makes all the difference. The ease of sourcing polyestergaren, combined with its robust performance, is why it continues to dominate as the preferred yarn type across many industries.

Comparing Polyester Spun Yarn with Other Yarn Types

When conducting a yarn comparison, Gesponnen polyester garen often stands out. Compared to cotton, it provides better wrinkle resistance and quicker drying times. Versus nylon, it is more cost-effective and has superior UV resistance. Against wool, it wins in washability and allergen-free composition.

These differences make it a smart choice for a variety of use cases, especially in areas where durability, ease of maintenance, and budget constraints are important. In both durable textiles en quality fabrics, spun polyester holds a distinct advantage that few other yarns can match.

Cost-effective yarn

In the ever-demanding world of textile manufacturing and design, Gesponnen polyester garen has proven time and again to be a material that strikes the perfect balance between performance, cost, and versatility. Its superior durability, color retention, and broad applicability make it a logical choice for everything from everyday clothing to heavy-duty industrial fabrics.

The move toward sustainable textiles has only enhanced the relevance of spun polyester, especially with innovations in recycled yarns and hybrid blends. Designers value it for its adaptability, while manufacturers rely on it for consistency and efficiency in production.

Whether you’re producing high-fashion garments, industrial filters, or home furnishings, Gesponnen polyester garen continues to deliver unmatched value. As the textile landscape continues to evolve, investing in this cost-effective yarn ensures that you remain competitive, responsible, and ready to meet the demands of modern consumers. With its remarkable blend of benefits, it’s no wonder that Gesponnen polyester garen remains the top choice for quality fabrics worldwide.

Bijvoorbeeld: "Wil je meer weten over Gesponnen polyester garen? Neem nu contact met ons op voor een offerte!"

Vorig nieuws

Hoe naaigarens worden geclassificeerd in China: EEN G...Volgend nieuws

Polyester gesponnen garen Een veranderende beleidsomgeving

Door Garen

Functie Product

-

DTY 100D/144F Polyester garen

DTY 100D/144F Polyester garenDTY 100D/144F Polyester Garen: De Ultieme Gidsen...

-

DTY 100D/96F Polyester Garen

DTY 100D/96F Polyester GarenDTY 100D/96F Polyester Garen: De zachte, stabiele...

-

DTY 75D/144F SIM Polyester Garen

DTY 75D/144F SIM Polyester GarenDTY 75D/144F SIM Polyester Garen: Een topkeuze voor...