Polyester sewing thread is one of the most commonly used types of sewing thread due to its high strength, excellent abrasion resistance, and superior color fastness. Among the various specifications of polyester thread, Polyester sewing thread 50/2 and Polyester sewing thread 50/3 are two of the most widely used. These threads differ in structure and performance, making them suitable for different sewing applications. In this article, we will provide a detailed comparison of Polyester sewing thread 50/2 and Polyester sewing thread 50/3, covering their key characteristics, applications, and tips for selection to help you better understand and choose the right thread for your sewing needs.

In the apparel industry, Polyester sewing thread 50/2 is ideal for lightweight garments like shirts, dresses, and lingerie, offering subtle stitching that complements delicate fabrics without compromising their appearance. Conversely, Polyester sewing thread 50/3 is better suited for heavier garments such as jeans, jackets, and outerwear, where strength and durability are essential. In-home textiles, 50/2 is commonly used for stitching lighter items like bed sheets, pillowcases, and duvet covers, ensuring a smooth, inconspicuous seam, while 50/3 is used for heavier textiles like curtains, sofas, and cushions, where the thread’s strength is necessary to handle daily use. Industrial applications require a high strength of 50/3, making it the preferred choice for products such as bags, shoes, automotive upholstery, and seat covers, which require robust seams. On the other hand, 50/2 is less common in industrial settings but may be used in lighter applications that don’t demand as much durability.

When choosing between the two, the thickness of the fabric is crucial—50/2 works best with lightweight materials like silk and chiffon, while 50/3 excels with heavier fabrics like denim and canvas. If the project requires fine, delicate stitching, 50/2 is the go-to, whereas, for stronger seams capable of withstanding heavy use, 50/3 is the better choice. For heavy-duty projects that demand high abrasion resistance, such as bags or upholstery, 50/3 ensures long-lasting durability, while 50/2 suffices for moderate durability needs, like shirts or bed linens.

-

Thread Diameter and Strength

Thread Diameter and StrengthThe primary difference between Polyester sewing thread 50/2 and Polyester sewing thread 50/3 lies in their construction and strength. Polyester sewing thread 50/3 is made by twisting three single filaments together, resulting in a thicker diameter and higher tensile strength. This makes it more durable, and suitable for heavy-duty applications. On the other hand, Polyester sewing thread 50/2 is constructed by twisting only two filaments, resulting in a thinner diameter and relatively lower strength, which is ideal for lightweight applications.

-

Schuurweerstand

SchuurweerstandDue to the thicker diameter of Polyester sewing thread 50/3, it exhibits superior abrasion resistance compared to Polyester sewing thread 50/2. This makes it better suited for areas subject to frequent friction, such as seams that undergo regular wear or high-stress applications. Polyester sewing thread 50/2, with its finer diameter, is less durable in such conditions.

-

Softness and Smoothness

Softness and SmoothnessWhile Polyester sewing thread 50/3 offers higher strength, Polyester sewing thread 50/2 is softer and smoother due to its thinner construction. This results in less noticeable stitching, making 50/2 ideal for delicate fabrics where fine, subtle seams are required. Polyester sewing thread 50/3, being thicker, may leave more visible seams, which can be desirable in heavy-duty applications but may detract from the appearance of lighter materials.

-

Recommended Fabric Use

Recommended Fabric UsePolyester sewing thread 50/2 is particularly suitable for lightweight fabrics such as silk, chiffon, and fine cotton, where the thread needs to blend seamlessly with the material. Polyester sewing thread 50/3, with its thicker diameter, is better suited for heavier fabrics like denim, canvas, and upholstery materials. When choosing between the two, fabric thickness plays a crucial role in determining the appropriate thread.

-

Raadpleging

Het aanpassingsproces begint met een gedetailleerd adviesgesprek, waarin we de specifieke behoeften van de klant bespreken, inclusief draaddikte, kleurvereisten en toepassingsspecifieke eisen. Ons team van experts werkt nauw samen met de klant om hun unieke eisen te begrijpen en aanbevelingen te doen.

Het aanpassingsproces begint met een gedetailleerd adviesgesprek, waarin we de specifieke behoeften van de klant bespreken, inclusief draaddikte, kleurvereisten en toepassingsspecifieke eisen. Ons team van experts werkt nauw samen met de klant om hun unieke eisen te begrijpen en aanbevelingen te doen. -

Offerte

Zodra de vereisten duidelijk zijn gedefinieerd, maken we een gedetailleerde offerte waarin de kosten, levertijd en andere relevante details worden beschreven. Onze offertes zijn transparant en uitgebreid, zodat klanten een duidelijk inzicht hebben in de kosten.

Zodra de vereisten duidelijk zijn gedefinieerd, maken we een gedetailleerde offerte waarin de kosten, levertijd en andere relevante details worden beschreven. Onze offertes zijn transparant en uitgebreid, zodat klanten een duidelijk inzicht hebben in de kosten. -

Productie

Ons productieproces is zeer efficiënt en kwaliteitsgericht, zodat de op maat gemaakte draden voldoen aan de hoogste normen op het gebied van prestaties en duurzaamheid. We gebruiken ultramoderne apparatuur en strenge kwaliteitscontrolemaatregelen om garens te produceren die de industrienormen overtreffen.

Ons productieproces is zeer efficiënt en kwaliteitsgericht, zodat de op maat gemaakte draden voldoen aan de hoogste normen op het gebied van prestaties en duurzaamheid. We gebruiken ultramoderne apparatuur en strenge kwaliteitscontrolemaatregelen om garens te produceren die de industrienormen overtreffen. -

Verzending

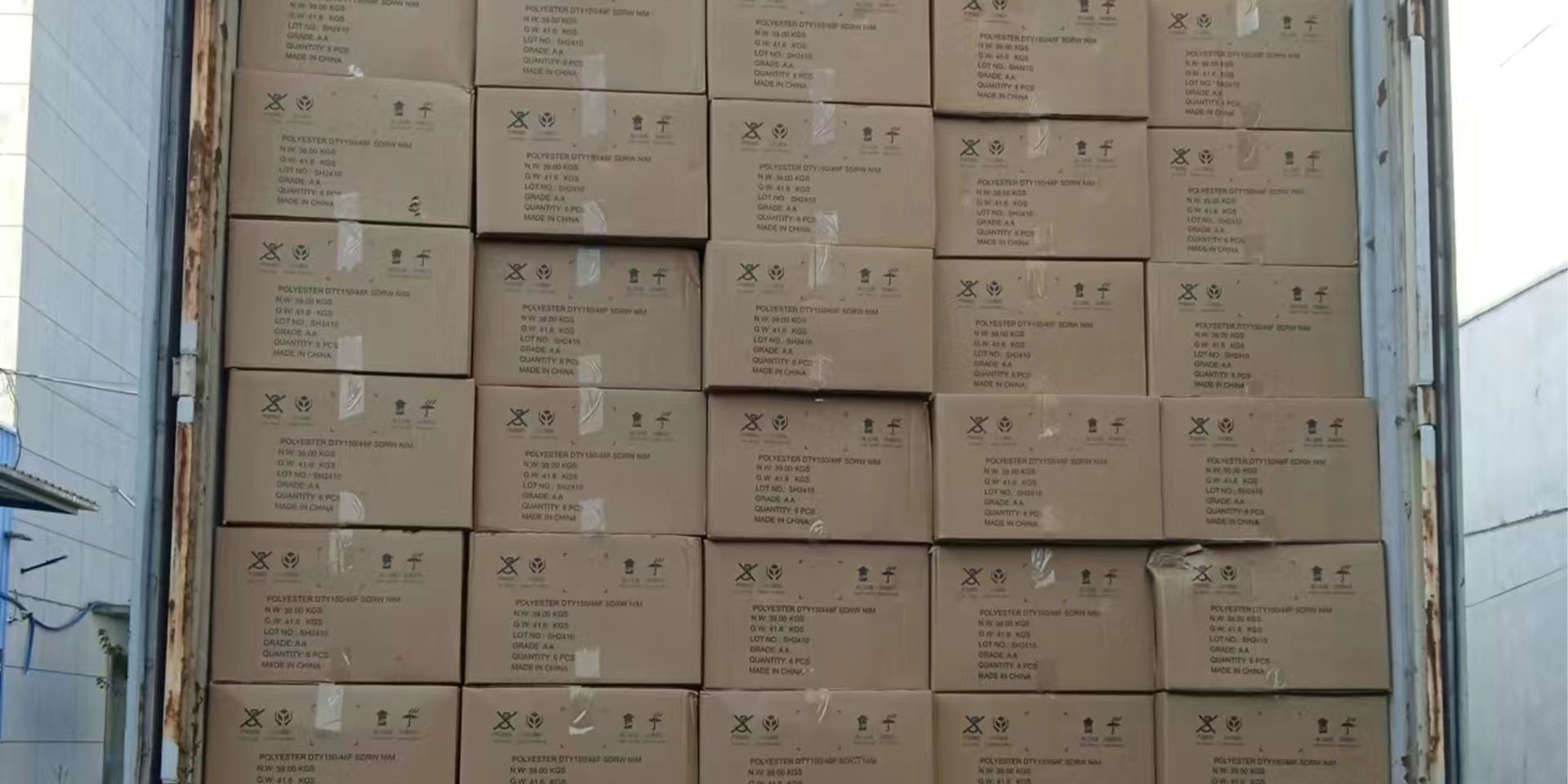

Na de productie worden de op maat gemaakte garens zorgvuldig verpakt en binnen de afgesproken tijd naar de klant verzonden. We bieden betrouwbare logistieke oplossingen om ervoor te zorgen dat de garens de klant snel en in perfecte staat bereiken.

Na de productie worden de op maat gemaakte garens zorgvuldig verpakt en binnen de afgesproken tijd naar de klant verzonden. We bieden betrouwbare logistieke oplossingen om ervoor te zorgen dat de garens de klant snel en in perfecte staat bereiken.

-

What is the specific difference between Polyester sewing thread 50/2 and 50/3?

Polyester sewing thread 50/2 is made of two strands of yarn, suitable for sewing light fabrics, with lower strength and suitable for fine sewing; while Polyester sewing thread 50/3 is made of three strands of yarn, with a thicker thread diameter and higher strength, suitable for sewing heavier fabrics and applications requiring higher durability.

-

Should I choose 50/2 or 50/3 to sew my product?

If your product uses light fabrics (such as silk, chiffon, etc.), it is recommended to choose 50/2, which can provide fine sewing effects; if it is heavy fabrics (such as denim, canvas, home furnishings, etc.), choose 50/3 because its strength and wear resistance are more suitable for these heavy fabrics.

-

In home textile products, what are the differences in specific scenarios for 50/2 and 50/3?

In home textile products, 50/2 is suitable for thin items such as bed sheets, quilt covers, pillowcases, etc., and can provide delicate stitching; while 50/3 is suitable for items such as curtains, sofa covers, cushions, etc. that need to withstand greater tension and durability.

-

How to determine the appropriate needle size and sewing tension?

For 50/2, it is recommended to use a thinner needle (such as 9-11 needle) and adjust the tension of the sewing machine to avoid too tight bottom thread affecting the sewing effect. For 50/3, you may need to slightly increase the needle size (such as 11-14 needle) to ensure strength and durability. Make sure the ratio of needle eye to sewing thread is 1:1.2, which can ensure smooth sewing effect.

-

I need a special color, can the customized service meet it? Can the customized color be guaranteed to be exactly the same as the sample I provided?

Our customized service can meet your special color needs. We use advanced dyeing technology and professional color matching system to ensure that the customized color is highly consistent with the sample you provide. Before production, we will provide samples for your confirmation to ensure that the color meets your requirements. If necessary, we can also perform color management according to your brand standards to ensure the color stability of each batch.

-

What are the color options for these threads?

Polyester Sewing Thread 50/2 and 50/3 are available in a variety of colors, and customers can customize the color as needed to meet different design requirements.

-

Als ik kies voor een aangepaste service, hoe lang duurt het dan van bestelling tot levering? Kan het versneld worden?

De doorlooptijd voor maatwerkservices hangt meestal af van de complexiteit van het maatwerk en het ordervolume. Over het algemeen duurt het 15-25 werkdagen van bestelling tot levering. Als je project dringend is, kunnen we je een snelle service bieden. We zullen het productieplan afstemmen op uw specifieke behoeften om een tijdige levering te garanderen.

-

Wat zijn de kwaliteitsnormen van deze twee naaigarens? Zijn er relevante certificeringen of testrapporten beschikbaar?

Onze naaigarens volgen strikt de internationale kwaliteitsnormen, waaronder de ISO 9001-certificering van het kwaliteitsmanagementsysteem en de OEKO-TEX Standaard 100-milieucertificering. Elke partij producten ondergaat strenge kwaliteitstesten, waaronder trektesten, slijtvastheidstesten, kleurechtheidstesten, enz. We kunnen ook gedetailleerde testrapporten leveren op basis van uw behoeften om ervoor te zorgen dat de naaigarens die u gebruikt aan de hoogste normen voldoen.

-

Verstrekt u monsters om te testen?

Veel leveranciers bieden gratis monsters aan om te testen, maar het kan zijn dat klanten moeten betalen voor verzending. Het is aan te raden om het monsterbeleid met de leverancier te bespreken voordat je een bestelling plaatst.

-

Mijn bestelhoeveelheid kan relatief klein zijn. Is er een minimum bestelhoeveelheid vereist? Als de bestelde hoeveelheid klein is, heeft dit dan invloed op de prijs of levertijd?

We begrijpen dat klanten verschillende behoeften hebben, dus we proberen de minimale bestelhoeveelheid te verlagen om aan de behoeften van verschillende klanten te voldoen. Voor standaardspecificaties is de minimale bestelhoeveelheid 100 kilo; voor producten op maat is de minimale bestelhoeveelheid één container. Als de bestelde hoeveelheid klein is, doen we nog steeds ons best om aan uw wensen te voldoen, maar de eenheidsprijs kan worden aangepast op basis van de aanpassingskosten. De levertijd wordt meestal niet beïnvloed door kleine bestelhoeveelheden en we regelen de productie en levering volgens standaardprocedures.