Polyester Sewing Thread 40/2 and 40/3 are two popular specifications in the world of sewing threads, commonly used across various industries, including apparel, umbrellas, and home textiles. These threads are made from 100% polyester fibers, offering excellent strength, durability, resistance to shrinkage, and high color fastness. Ideal for a wide range of fabrics and sewing techniques, Polyester Sewing Thread 40/2 and 40/3 are perfect choices for both industrial sewing and handcrafts.

The main difference between Polyester Sewing Thread 40/2 and 40/3 lies in the thickness and strength of the threads. 40/3 is more suitable for heavier fabrics, while 40/2 is perfect for medium-weight materials. This distinction allows users to choose the appropriate thread based on the fabric’s weight and sewing requirements, ensuring optimal results in various applications.

-

Apparel Manufacturing: Polyester Sewing Thread 40/2 and 40/3 are ideal for the production of various types of clothing, such as shirts, jackets, and denim jeans. These threads offer excellent sewing performance, allowing them to be used on high-speed sewing machines while maintaining the aesthetic appearance and durability of the seams. Their robust characteristics ensure that the finished garments remain strong and long-lasting, even after repeated washing and wear.

-

Umbrella Production: One of the standout features of Polyester Sewing Thread 40/2 and 40/3 is their resistance to water and ultraviolet (UV) rays, making them the perfect choice for umbrella manufacturing. The threads can withstand the stresses and wear that umbrellas face in harsh weather conditions, ensuring the seams remain intact and functional for an extended period of time. Polyester’s inherent resistance to moisture and UV degradation guarantees that umbrellas sewn with these threads remain durable and aesthetically pleasing.

-

Têxteis-lar: Polyester Sewing Thread 40/2 and 40/3 are also commonly used in home textiles, such as curtains, bed linens, and sofa covers. These threads provide outstanding durability and color retention, even when subjected to daily use and regular washing. The threads’ ability to maintain their strength and color vibrancy makes them a perfect choice for items that require longevity and resilience in high-traffic areas of the home.

-

Other Uses: In addition to their use in apparel, umbrellas, and home textiles, Polyester Sewing Thread 40/2 and 40/3 are versatile enough to be applied in various other industries, such as crafting and outdoor products. From handmade accessories to tents and outdoor gear, these threads demonstrate their adaptability and ability to perform well in different conditions. Whether used in light or heavy-duty projects, Polyester Sewing Thread 40/2 and 40/3 deliver consistent results.

-

Durability

DurabilityPolyester threads are known for their high abrasion resistance, ensuring that sewn products last longer without showing signs of wear. This durability is essential for items that are exposed to frequent friction, such as clothing, upholstery, and outdoor gear.

-

Solidez da cor

Solidez da corPolyester Sewing Thread 40/2 and 40/3 boast excellent color retention, which is particularly important for items like apparel and home textiles that are washed frequently. The threads’ ability to retain their color over time ensures that the products remain aesthetically pleasing and vibrant.

-

Chemical Resistance

Chemical ResistancePolyester is inherently resistant to a wide range of chemicals, making these threads suitable for use in various environments, including those exposed to detergents, oils, and other industrial substances. This feature ensures the longevity and reliability of the sewn items in a variety of conditions.

-

Resistência ao calor

Resistência ao calorPolyester threads are also resistant to high temperatures, making them ideal for applications where heat exposure is a concern, such as sewing for industrial or automotive products. This heat resistance prevents the threads from melting or degrading under heat stress.

-

Consulta

O processo de personalização começa com uma consulta detalhada, onde discutimos as necessidades específicas do cliente, incluindo a espessura do fio, os requisitos de cor e as exigências específicas da aplicação. A nossa equipa de especialistas trabalha em estreita colaboração com o cliente para compreender os seus requisitos únicos e fornecer recomendações.

O processo de personalização começa com uma consulta detalhada, onde discutimos as necessidades específicas do cliente, incluindo a espessura do fio, os requisitos de cor e as exigências específicas da aplicação. A nossa equipa de especialistas trabalha em estreita colaboração com o cliente para compreender os seus requisitos únicos e fornecer recomendações. -

Cotação

Assim que os requisitos estiverem claramente definidos, fornecemos um orçamento detalhado que descreve o custo, o prazo de entrega e outros pormenores relevantes. Os nossos orçamentos são transparentes e completos, assegurando que os clientes têm uma compreensão clara dos custos envolvidos.

Assim que os requisitos estiverem claramente definidos, fornecemos um orçamento detalhado que descreve o custo, o prazo de entrega e outros pormenores relevantes. Os nossos orçamentos são transparentes e completos, assegurando que os clientes têm uma compreensão clara dos custos envolvidos. -

Produção

O nosso processo de produção é altamente eficiente e centrado na qualidade, garantindo que as roscas personalizadas cumprem os mais elevados padrões de desempenho e durabilidade. Utilizamos equipamento de ponta e medidas rigorosas de controlo de qualidade para produzir roscas que excedem os padrões da indústria.

O nosso processo de produção é altamente eficiente e centrado na qualidade, garantindo que as roscas personalizadas cumprem os mais elevados padrões de desempenho e durabilidade. Utilizamos equipamento de ponta e medidas rigorosas de controlo de qualidade para produzir roscas que excedem os padrões da indústria. -

Expedição

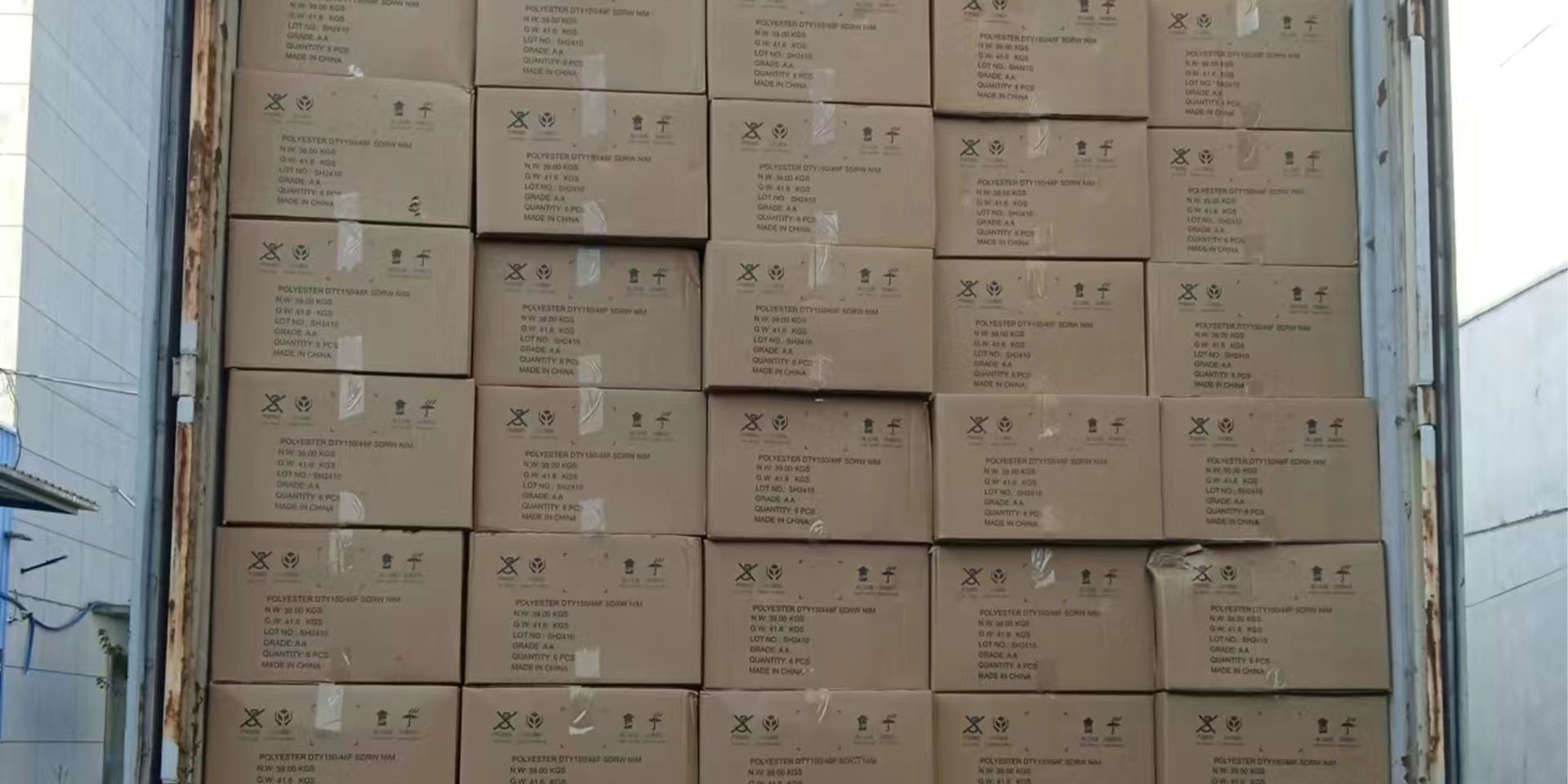

Após a produção, as linhas personalizadas são cuidadosamente embaladas e enviadas para o cliente dentro do prazo acordado. Oferecemos soluções logísticas fiáveis para garantir que as linhas chegam ao cliente rapidamente e em perfeitas condições.

Após a produção, as linhas personalizadas são cuidadosamente embaladas e enviadas para o cliente dentro do prazo acordado. Oferecemos soluções logísticas fiáveis para garantir que as linhas chegam ao cliente rapidamente e em perfeitas condições.

-

What is the main difference between Polyester Sewing Thread 40/2 and 40/3?

The main difference between 40/2 and 40/3 is the thickness and strength of the thread. 40/3 is more suitable for thicker fabrics, while 40/2 is suitable for medium-thick fabrics.

-

What types of fabrics are suitable for these two wires?

What types of fabrics are suitable for these two wires? 40/2 is suitable for medium-thick fabrics, such as shirts, jackets, etc.; 40/3 is suitable for thicker fabrics, such as denim, tents, etc.

-

How durable are Polyester Sewing Thread 40/2 and 40/3?

Both threads are made of 100% polyester fiber, which has the characteristics of high strength, abrasion resistance, shrinkage resistance and high color fastness, ensuring the long-term durability of the sewing thread.

-

Preciso de uma cor especial, o serviço personalizado pode satisfazê-la? É possível garantir que a cor personalizada é exatamente igual à da amostra que forneci?

O nosso serviço personalizado pode satisfazer as suas necessidades especiais de cor. Usamos tecnologia de tingimento avançada e sistema profissional de correspondência de cores para garantir que a cor personalizada seja altamente consistente com a amostra fornecida. Antes da produção, forneceremos amostras para sua confirmação para garantir que a cor atenda às suas necessidades. Se necessário, também podemos efetuar a gestão da cor de acordo com os padrões da sua marca para garantir a estabilidade da cor de cada lote.

-

What are the color options for these threads?

Polyester Sewing Thread 40/2 and 40/3 are available in a variety of colors, and customers can customize the color as needed to meet different design requirements.

-

Se optar por um serviço personalizado, quanto tempo é que demora desde a encomenda até à entrega? Pode ser acelerado?

O prazo de entrega dos serviços personalizados depende normalmente da complexidade da personalização e do volume da encomenda. De um modo geral, são necessários 15-25 dias úteis desde a encomenda até à entrega. Se o seu projeto tiver necessidades urgentes, podemos fornecer serviços acelerados. Organizaremos o plano de produção de acordo com as suas necessidades específicas para garantir a entrega atempada.

-

Quais são as normas de qualidade destas duas linhas de costura? Existem certificações ou relatórios de ensaio relevantes disponíveis?

As nossas linhas de costura seguem rigorosamente as normas de qualidade internacionais, incluindo a certificação do sistema de gestão da qualidade ISO 9001 e a certificação ambiental OEKO-TEX Standard 100. Cada lote de produtos será submetido a rigorosos testes de qualidade, incluindo testes de tração, testes de resistência à abrasão, testes de solidez da cor, etc. Também podemos fornecer relatórios de teste detalhados de acordo com as suas necessidades para garantir que as linhas de costura que utiliza cumprem os padrões mais elevados.

-

Fornecem amostras para ensaio?

Muitos fornecedores fornecem amostras gratuitas para os clientes testarem, mas os clientes podem ter de pagar o envio. Recomenda-se que confirme a política de amostras com o fornecedor antes de efetuar uma encomenda.

-

A minha quantidade de encomenda pode ser relativamente pequena. Existe um requisito de quantidade mínima de encomenda? Se a quantidade da encomenda for pequena, isso afectará o preço ou o prazo de entrega?

Compreendemos que os clientes têm necessidades diversas, pelo que tentamos reduzir a quantidade mínima de encomenda para satisfazer as necessidades dos diferentes clientes. Para especificações padrão, a quantidade mínima de encomenda é de 100 quilogramas; para produtos personalizados, a quantidade mínima de encomenda é de um contentor. Se a quantidade da sua encomenda for pequena, faremos o nosso melhor para satisfazer as suas necessidades, mas o preço unitário pode ser ajustado de acordo com o custo de personalização. O tempo de entrega geralmente não é afetado por pequenas quantidades de encomenda, e nós organizaremos a produção e a entrega de acordo com os procedimentos padrão.