The role of Polyester POY in global yarn manufacturing is critical for DTY, FDY, and technical textiles. Discover its applications, 2025 market trends, supplier checklist, and sourcing strategies to secure quality, sustainability, and compliance.

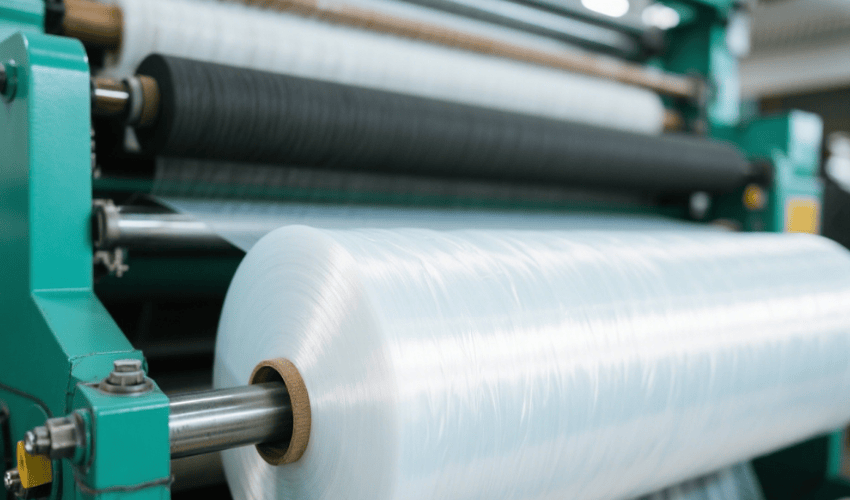

Polyester POY (Pre-Oriented Yarn) is the backbone of the modern textile industry. Produced through high-speed spinning, it is a semi-drawn filament primarily used for further processing into DTY Yarn (Draw Textured Yarn) and FDY Yarn (Fully Drawn Yarn). In 2025, the global polyester yarn market is expected to surpass USD 125 billion, with Polyester POY as the largest intermediate material.

As demand for performance textiles, sustainable fabrics, and recycled polyester accelerates, buyers must carefully evaluate Polyester POY suppliers. Quality consistency, certifications (OEKO-TEX, GRS, REACH), and reliable capacity are now as critical as cost. This guide market trends, applications, risks, and sourcing strategies to help procurement teams make future-proof decisions in global yarn manufacturing.

Why Polyester POY Matters

Polyester dominates global fiber consumption, representing over 50% of the textile raw material market. At the center of this dominance lies POY Yarn—a semi-processed filament that serves as feedstock for downstream yarns like DTY and FDY.

Without Polyester POY, industries from apparel and home textiles to technical fabrics would struggle to meet the performance, cost, and sustainability requirements of today’s consumers. For sourcing managers, understanding the role of POY is not optional—it’s essential.

Polyester POY for clothing

Market Outlook and Growth

Rising Global Demand

-

In 2025, demand for polyester yarns is projected at 60 million tons.

-

Over 70% of DTY Yarn comes from POY, reinforcing its role as a strategic feedstock.

-

Growth is fueled by sportswear, fast fashion, and industrial textiles.

Sustainability Drivers

-

Recycled Polyester POY (rPOY), made from PET bottles, is expanding at double-digit growth.

-

Buyers increasingly demand GRS-certified Polyester POY to align with ESG goals.

Competitive Pressures

-

China and India dominate production.

-

New entrants bring competitive pricing, but quality and compliance vary significantly.

Applications of POY in Yarn Manufacturing

1. Texturizing into DTY

The most important use of POY is in draw-texturing machines to produce DTY Yarn, which is elastic, bulked, and widely used in sportswear and home textiles.

2. Direct Weaving and Knitting

Some Polyester POY can be twisted and used directly for weaving and knitting, offering strength and smoothness.

3. Technical Textiles

High-tenacity POY serves as the base for airbags, seat belts, tents, and industrial fabrics.

4. Sustainable Yarns

Recycled Polyester POY is the feedstock for sustainable DTY, aligning with global recycling initiatives.

Polyester POY vs DTY vs FDY

| Yarn Type | Characteristics | End Use |

|---|---|---|

| POY | Semi-drawn, requires further processing | Feedstock for DTY, FDY |

| DTY | Bulked, elastic, textured | Sportswear, upholstery, home textiles |

| FDY | Fully drawn, smooth | Knitting, weaving, apparel |

Key Specifications to Evaluate

When sourcing Polyester POY Yarn, buyers should check:

-

Denier Range (50D–600D): Determines fineness of fabric.

-

Filament Count (36F–288F): Impacts texture and softness.

-

Lustre (Semi-dull, Bright, Trilobal): Affects fabric aesthetics.

-

Strength & Uster Evenness: Key for high-speed weaving and knitting.

-

Virgin vs Recycled: Growing demand for rPOY in global supply chains.

Risks of Choosing the Wrong Supplier

-

Customs Rejection: Non-compliant POY can be refused at EU/US ports.

-

Production Failures: Inconsistent denier and filament quality cause breakage in texturizing.

-

Reputation Damage: Poor-quality yarn leads to customer complaints in apparel markets.

-

Hidden Costs: Rework, delays, and air freight inflate procurement budgets.

Polyester POY for tents

The 30-Question Polyester POY Supplier Checklist

Company & Capacity

-

What is your monthly Polyester POY production capacity?

-

Do you own the spinning facility or outsource?

-

Which export markets do you currently serve?

Product Quality

4. What denier/filament options do you provide?

5. Can you supply Uster evenness reports?

6. How do you control quality across large lots?

Certifications

7. Do you provide OEKO-TEX certificates?

8. Are your products GRS-certified?

9. Can you guarantee REACH compliance?

Customization

10. Do you offer dope-dyed POY?

11. What’s the MOQ for custom colors?

12. Can you adjust lustre (semi-dull, bright, trilobal)?

Logistics & Delivery

13. What’s your lead time during peak season?

14. Do you offer mixed-container shipments?

15. How do you manage seasonal demand spikes?

Commercial Terms

16. What are your FOB price tiers by volume?

17. Do you offer trial orders before bulk contracts?

18. What after-sales technical support is included?

Polyester POY Suppliers

Cost Drivers in Polyester POY Sourcing

-

Raw Material Prices (PTA & MEG)

-

Denier & Filament Range (finer yarn = higher cost)

-

Recycled vs Virgin (rPOY is 10–20% more expensive)

-

Coloring Method (dope-dyed increases cost)

-

Order Volume (higher tonnage = lower unit cost)

-

Export Logistics (container optimization reduces freight cost)

Pro Tip: Always request a detailed cost breakdown separating raw material, processing, packaging, and logistics.

Supplier Evaluation Process

Step 1: Pre-Qualification – Screen suppliers via trade references & online profiles.

Step 2: Documentation Review – Request certifications, specs, Uster reports.

Step 3: Sample Testing – Test yarn for strength, evenness, and processability.

Step 4: Facility Audit – Inspect spinning and QC processes.

Step 5: Trial Order – Start with smaller lots to assess reliability.

Frequently Asked Buyer Questions

Q1: What is Polyester POY used for?

A: Mainly for producing DTY and FDY Yarn, as well as weaving, knitting, and industrial fabrics.

Q2: Is Polyester POY eco-friendly?

A: Yes, through Recycled POY (rPOY) made from PET bottles.

Q3: How do I choose between semi-dull and bright POY?

A: Semi-dull for casual/home textiles; bright or trilobal for shiny fashion fabrics.

Q4: Where is Polyester POY mainly produced?

A: China and India, accounting for more than 70% of global supply.

Q5: What certifications should I request?

A: OEKO-TEX, GRS, and REACH compliance.

Polyester POY for seat belts

Polyester POY Yarn plays a critical role in global yarn manufacturing, serving as the feedstock for DTY, FDY, and technical textiles. For buyers, success depends on choosing suppliers that deliver consistent denier quality, international certifications, and recycled options.

By following a structured sourcing process—including certification checks, sample testing, and supplier audits—procurement teams can secure a reliable, future-proof Polyester POY supply chain.

Tin tức trước đó

Top 10 Applications of DTY Yarn in Modern TextilesTin tức tiếp theo

DTY vs FDY: Which Polyester Yarn Works Best for...

Bởi Yarn

Sản phẩm nổi bật

-

Sợi polyester DTY 100D/144F

Sợi polyester DTY 100D/144FSợi polyester DTY 100D/144F: Hướng dẫn tối ưu...

-

Sợi polyester DTY 100D/96F

Sợi polyester DTY 100D/96FSợi polyester DTY 100D/96F: Mềm mại, ổn định...

-

Sợi polyester DTY 75D/144F SIM

Sợi polyester DTY 75D/144F SIMSợi polyester DTY 75D/144F SIM: Lựa chọn hàng đầu cho...