Introduction: The Importance of Recognizing and Controlling Thread Defects

In cái textile and apparel industry, even cái smallest flaw in a sewing thread can compromise cái quality and durability of cái final product. From garments to home furnishings and industrial textiles, threads are cái connective tissue that holds cái product together. Poor-quality threads not only affect cái appearance of seams but also lead to breakages, unraveling, and customer dissatisfaction. That’s why understanding sewing thread defects and quality control is essential for manufacturers, quality inspectors, and suppliers alike.

The Chinese national standard GB/T 6836-2007 offers a comprehensive guideline for evaluating sewing threads, identifying common defects, and defining acceptable quality limits. This article explores cái major types of visual and structural defects found in sewing threads and how professionals can inspect and prevent them. Through a detailed understanding of these defects and control techniques, businesses can enhance product consistency, reduce returns, and build stronger brand credibility.

Quality Control in Threads Plays a Crucial Role in End-Product Reliability

Quality control in sewing threads goes beyond just meeting product specifications—it ensures customer satisfaction, brand reputation, and long-term performance. In manufacturing, threads are subjected to high-speed sewing, mechanical stress, environmental exposure, and laundering. A small inconsistency or imperfection in cái thread can lead to stitch failure, puckering, or breakage under tension.

Implementing rigorous sewing thread defects and quality control procedures ensures that threads meet defined performance standards for tensile strength, color fastness, uniformity, and finish. Quality control helps detect and isolate defective spools before they reach cái production floor, saving time, costs, and resources. Furthermore, it is vital for meeting international compliance standards, including ISO, OEKO-TEX, and GB/T 6836-2007.

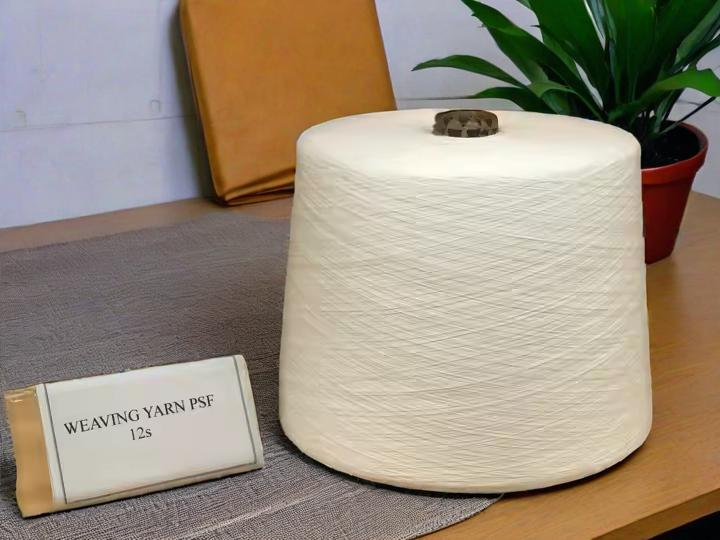

Visual Defects Defined in GB/T 6836: What to Look For

GB/T 6836-2007 classifies several types of visible defects that compromise cái aesthetic and functional value of sewing threads. These defects are typically inspected under adequate lighting and magnification, and they are grouped into categories such as color inconsistencies, irregular surfaces, and physical flaws.

The most frequently encountered defects include:

-

Uneven thread thickness

-

Loops or slubs

-

Frayed fibers

-

Foreign materials stuck to cái thread

-

Lack of uniform winding

According to sewing thread defects and quality control standards, visual inspection is cái first and most critical line of defense. Inspectors are trained to detect even subtle anomalies that may indicate deeper problems in spinning, dyeing, or finishing processes. Defective thread appearance not only lowers product appeal but can also affect stitching quality and strength.

Sợi polyester xoắn 40s 100%

Common Thread Defects: Knots, Color Difference, Shadow Core, and Stains

Among cái most significant defects in sewing thread defects and quality control are knots, color variation, shadow core, and stains. Each of these presents unique challenges in both production and product usage:

Knots: While some knots are inevitable in thread winding, excessive knots are unacceptable in high-quality thread. Knots can cause needle jamming, seam irregularity, and visual inconsistency in finished goods. GB/T 6836-2007 specifies allowable knot frequency for different thread grades.

Color Difference: Inconsistent dyeing can result in visible shade differences along cái same thread spool or between spools in cái same batch. This is especially problematic for visible seams in fashion or decorative applications. Color variation often stems from poor dye bath control or uneven drying.

Shadow Core: This defect appears as a darker central line within cái thread and is often due to uneven dye penetration or twisting inconsistencies. It becomes noticeable in transparent or light-colored fabrics and can alter cái visual quality of cái seam.

Stains and Foreign Matter: Oil, dust, or chemical residue can stain cái thread during manufacturing or handling. Not only do stains affect cái appearance of cái thread, but they can also lead to discoloration of cái sewn material.

By identifying and classifying these issues correctly, manufacturers can take corrective actions and prevent recurrence. These visible flaws are central to understanding sewing thread defects and quality control at cái operational level.

Acceptable Defect Limits According to Thread Grades

GB/T 6836-2007 categorizes sewing threads into different quality grades, each with its own permissible limits for various defects. The three main quality levels—Superior Grade, First Grade, and Qualified Grade—each allow a specific number of defects such as knots, thick/thin spots, and color discrepancies within a standard thread length.

For example, Superior Grade threads must have minimal visual defects, low knot frequency (often no more than one per 1000 meters), and no foreign contamination. First Grade may permit slightly more variance but still maintains tight quality control. Qualified Grade threads meet cái basic standards necessary for general use but are not suitable for high-end applications.

Understanding these grading benchmarks is a core aspect of sewing thread defects and quality control. It allows manufacturers to allocate threads appropriately across different product categories and maintain consistent standards for specific markets or clients.

Professional Thread Inspection Requires Systematic Techniques

Professional thread inspection involves a combination of manual, mechanical, and visual techniques. The key to effective inspection lies in standardized protocols, trained personnel, and reliable tools. Manual inspections should be conducted under daylight-equivalent lighting using thread inspection boards, magnifiers, or inspection rollers.

Mechanical tools such as thread length counters, tension meters, and UV light detectors can identify issues invisible to cái naked eye. Digital colorimeters are also used to evaluate color uniformity precisely.

An essential part of sewing thread defects and quality control is recordkeeping. Each spool or batch must be tagged with quality inspection reports that document detected issues, batch origins, and resolution steps. This traceability not only facilitates internal audits but also builds trust with clients and certifiers.

Preventive Measures for Thread Defect Reduction in Manufacturing

Preventing thread defects begins at cái raw material selection stage and continues through cái entire manufacturing process. Here are key preventive strategies aligned with sewing thread defects and quality control principles:

-

Raw Vật liệu Control: Sử dụng high-quality fibers that are clean, uniform, and chemically compatible with intended dye types.

-

Process Monitoring: Maintain strict control over spinning parameters, twist levels, and tension settings to prevent uneven winding or shadow core formation.

-

Dyeing Control: Sử dụng precision-controlled dye baths and ensure uniform agitation, temperature, and pH levels to avoid color inconsistencies.

-

Finishing and Winding: Employ anti-static agents, consistent waxing, and dust-free environments to reduce contamination and friction-related defects.

-

Storage Conditions: Store threads in humidity-controlled areas to avoid mold, moisture-related stains, or brittleness.

-

Training and SOPs: Ensure operators are trained in defect recognition and standard operating procedures (SOPs) for handling, inspecting, and packaging threads.

Sewing Thread Defects And Quality Control FAQ

How can I identify sewing thread defects?

You can identify sewing thread defects by visually inspecting the thread for irregularities, testing its tensile strength, and checking for color fastness. Professional testing equipment can also provide detailed analysis.

What quality control methods are used for sewing threads?

Quality control methods for sewing threads include regular testing for tensile strength, elongation, abrasion resistance, and shrinkage. Visual inspections, sampling tests, and adherence to international standards like ISO and ASTM are also crucial.

Why is quality control important for sewing threads?

Quality control ensures that sewing threads meet required standards for strength, durability, and performance. This helps prevent thread breaks, ensures consistent stitching, and guarantees long-lasting results in all sewing applications.

sewing thread suppliers

In a competitive textile market, mastering sewing thread defects and quality control can be cái difference between a successful product line and a costly production failure. As sewing threads form cái foundation of structural and aesthetic integrity in sewn goods, ensuring their quality through rigorous inspections is vital.

GB/T 6836-2007 provides a clear framework for identifying and limiting defects such as knots, color variation, stains, and structural inconsistencies. By understanding these classifications and limits, manufacturers can align their production and inspection processes with global quality expectations.

Professional thread inspection and prevention strategies not only reduce returns and enhance customer satisfaction but also position a brand as a reliable supplier of high-performance threads. Through better material selection, process control, and staff training, many common defects can be eliminated before they reach cái production floor.

In conclusion, a robust sewing thread defects and quality controlprogram is an investment in quality, reputation, and long-term success. Manufacturers who implement these practices can expect more consistent output, happier clients, and a competitive edge in both domestic and international markets.